Industrial Valves Manufacturer

Tianjin Jinqihang Valve Co., Ltd. is a well-known industrial valve manufacturer, focusing on the production of high-quality valve products. With extensive experience in the industry, we are committed ...

2014

ESTABLISHED

40+

MAJOR PROJECTS

30+

CERTIFICATIONS

13726

SQUARE METERS

40+

EMPLOYEES

VALVES CATEGORY

VALVES SOLUTIONS

The application of valves in various industries: Petroleum and petrochemical, water conservancy, chemical, heating, power, real estate

wawater Water Conservancy Project

Water diversion project, tap water, sewage treatment, etc.

Building

Commercial buildings, electronic plants, data centers, etc.

chemical industry

Pharmaceuticals, pesticides, dyes, etc

Last News

Unlocking Precision and Performance: The Advantages of Triple Eccentric Butterfly Valves

In high-demand industrial applications, precision, reliability, and long-term performance are non-ne... .

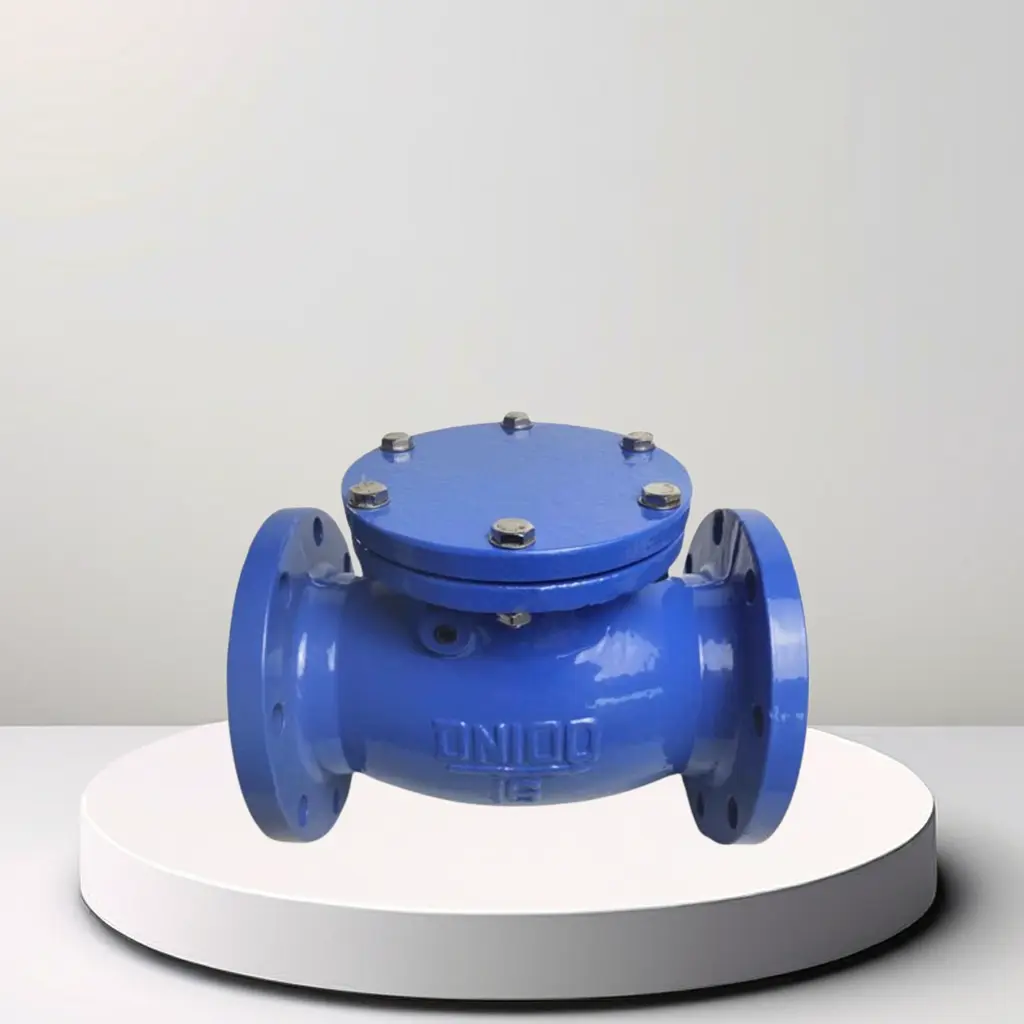

How to Select the Right Swing Check Valve for Your Project

Swing check valves are essential components in many fluid systems, designed to allow flow in one dir... .

Enhancing Fluid System Efficiency with Stainless Steel Threaded Y-Type Strainers

In fluid handling systems, maintaining the purity and performance of the medium is critical. One ess... .

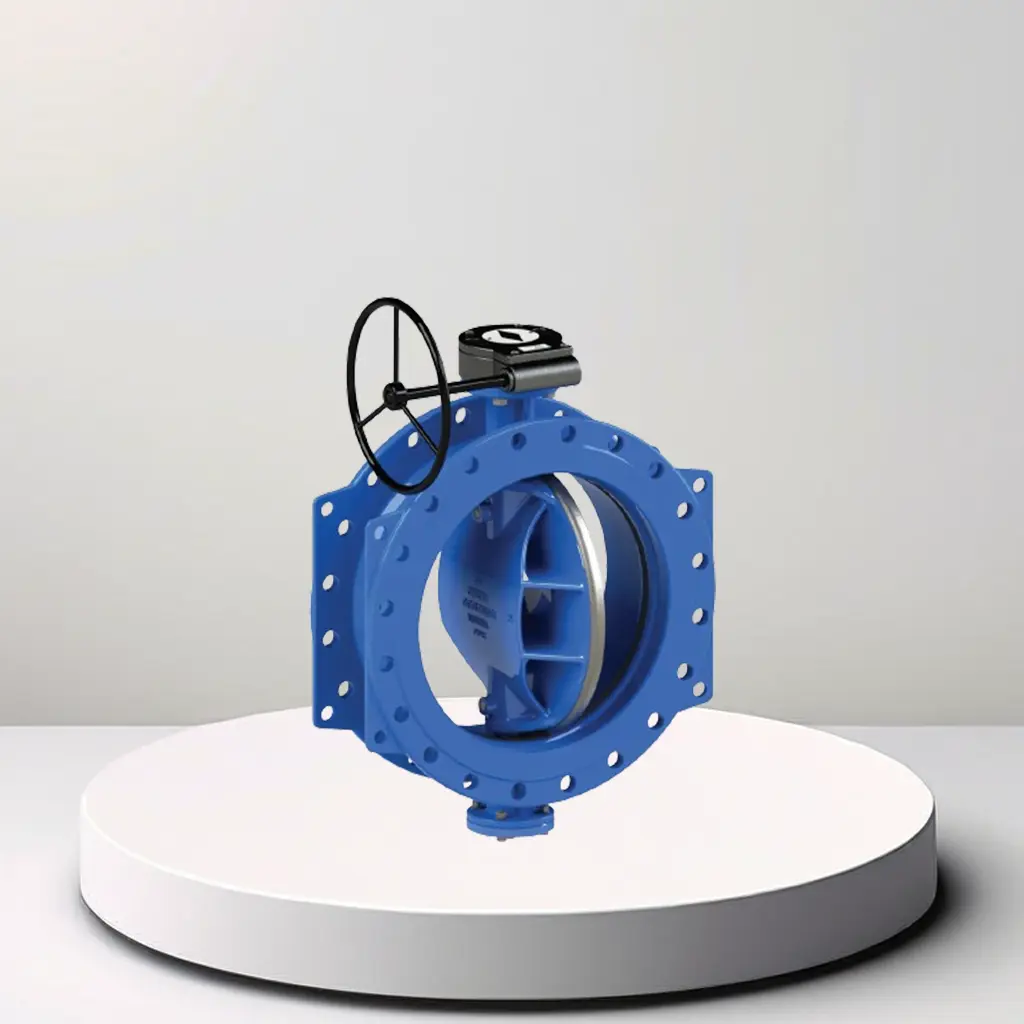

Why Choose a DI Wafer Butterfly Valve? Key Benefits for Modern Systems

In modern piping systems, efficiency, durability, and ease of maintenance are key priorities. Among ... .

Comprehensive Analysis of Double Eccentric Butterfly Valves: Structure, Advantages, and Applications

In modern industrial fluid control systems, the butterfly valve plays an essential role due to its c... .

From Material to Craftsmanship: A Closer Look at the Rise of Thickened Internal Thread Brass Ball Valves in the Market

In the ever-evolving world of fluid control, the thickened internal thread brass ball valve has emer... .