Product Description

The turbine head DI body wafer butterfly valve is a valve commonly used in industrial piping systems. Its design features and advantages make it very popular in many application fields. The following is a detailed introduction to this valve:

1. Main components

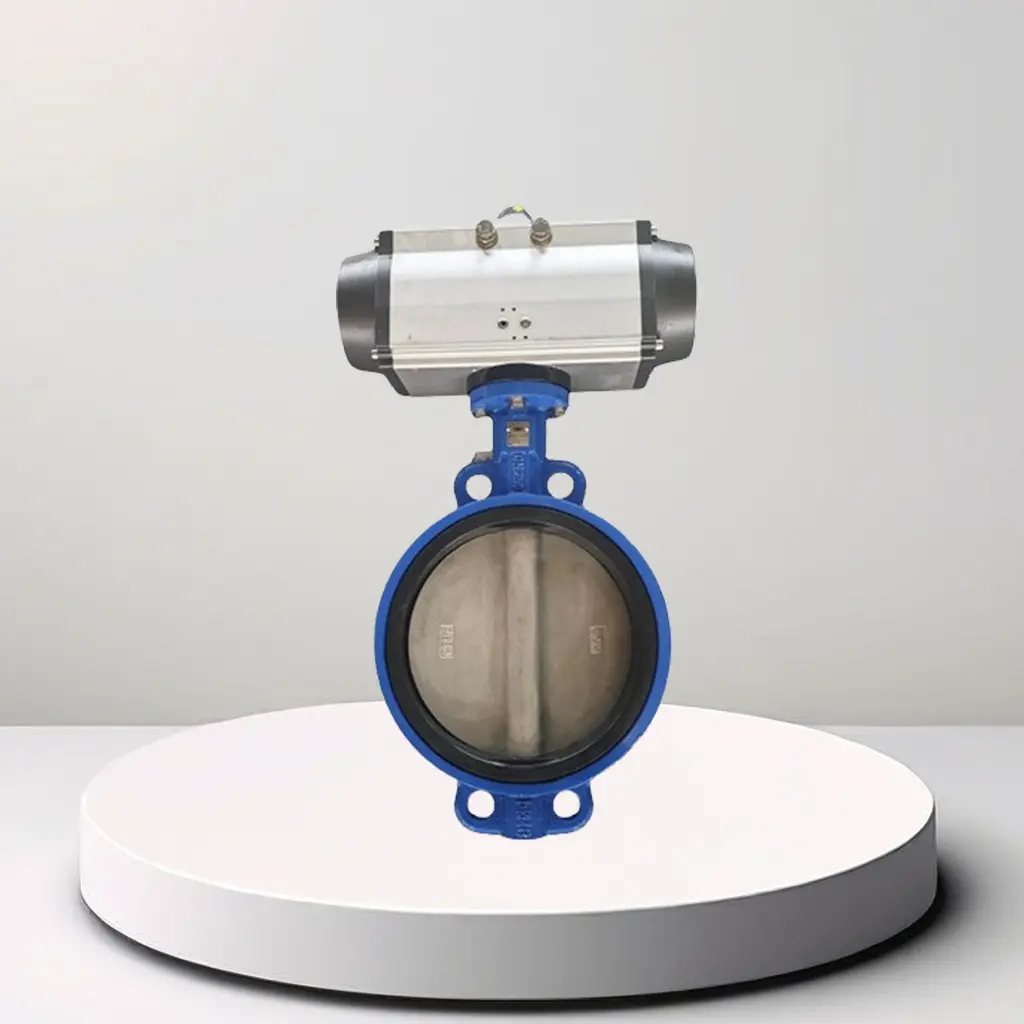

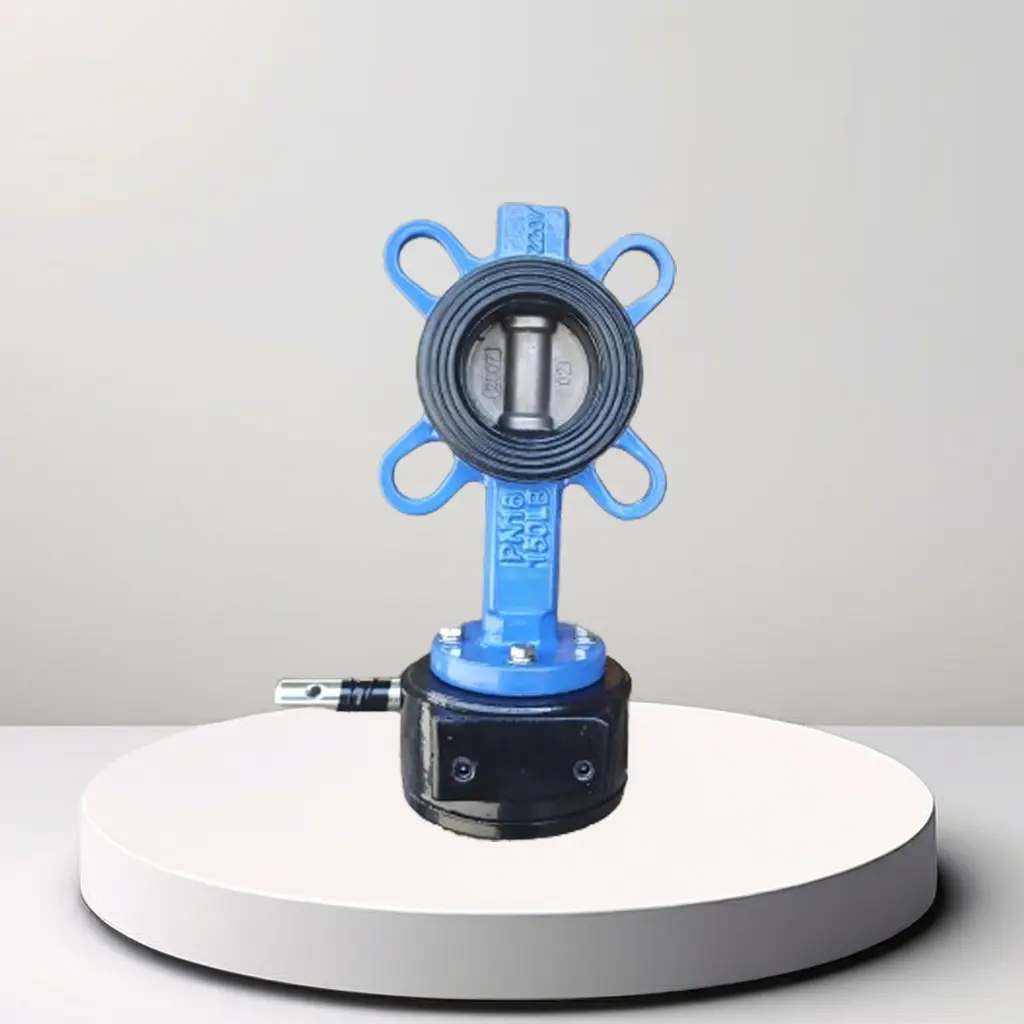

Gear Operated:

The turbine head is a manually operated device that drives the internal gear mechanism by rotating the handwheel to control the opening and closing of the butterfly valve. The turbine head operates smoothly and accurately, and is suitable for applications that require large torque.

DI Body:

The DI body refers to the main part of the valve, which is made of ductile iron. Ductile iron has high strength and toughness, can withstand high pressure and temperature, and also has good corrosion resistance.

Wafer Type:

The wafer butterfly valve adopts a wafer connection method. The valve is installed between two flanges and fixed by long bolts passing through the flange and the valve body. The wafer connection simplifies the installation and removal process, saving space and material costs.

2. Working Principle

The turbine head DI body wafer butterfly valve controls the rotation of the valve plate by rotating the turbine head handwheel, thereby opening, closing or regulating the fluid. The gear mechanism of the turbine head amplifies the rotational torque of the handwheel, making the operation easier and more precise.

3. Advantages

Easy to operate: The turbine head design makes valve operation easier and suitable for large-diameter valves or occasions requiring large operating torque.

Compact structure: The clamp design saves installation space and is suitable for pipeline systems with limited space.

Strong durability: Ductile iron material provides high mechanical strength and corrosion resistance, extending the service life of the valve.

Good sealing performance: Butterfly valves are usually equipped with sealing rings made of rubber or other materials to ensure good sealing performance and prevent leakage.

4. Application scenarios

Turbine head DI body clamp butterfly valves are widely used in the following fields:

Water supply and sewage treatment: used for fluid control and regulation in water treatment facilities.

Chemical and petroleum: suitable for pipeline systems of various chemical media and petroleum products.

Power and energy: used for steam, cooling water and other systems in power plants and energy facilities.

Food and pharmaceuticals: suitable for fluid control in the food and pharmaceutical industries with the selection of suitable sealing materials and surface treatment.

5. Installation and maintenance

Easy installation: The clamp design simplifies the installation process. Just clamp the valve between two flanges and tighten the bolts.

Easy maintenance: The valve has a simple structure and is easy to disassemble and maintain. The turbine head operating device is also convenient for maintenance and repair.

Regular inspection: Regularly check the operating status of the valve and turbine head to ensure that all parts are free of wear and corrosion and maintain good working performance.

Conclusion

The turbine head DI body wafer butterfly valve is a valve with excellent performance and easy operation. It is widely used in various industries due to its compact structure, easy installation and strong durability. It is suitable for pipeline systems that require reliable fluid control and regulation, and is an ideal choice for industrial pipeline control.