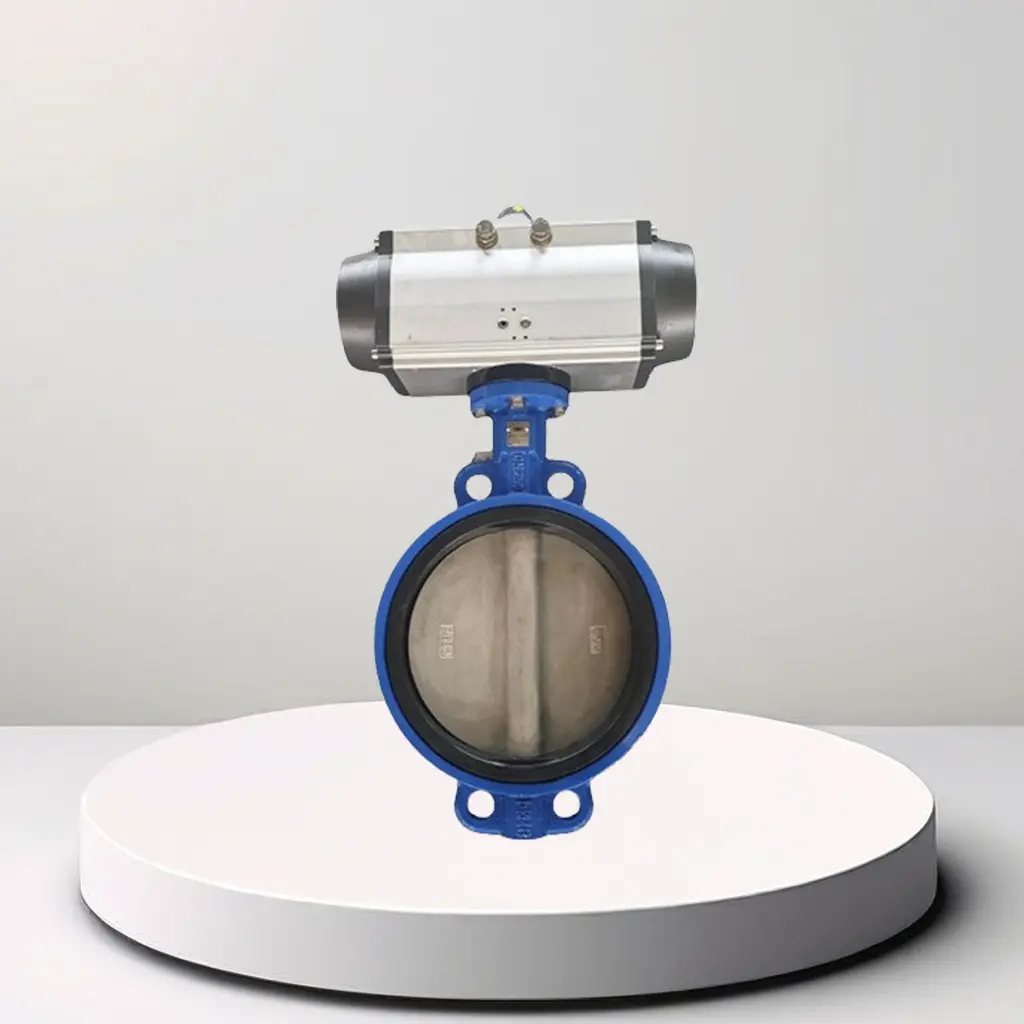

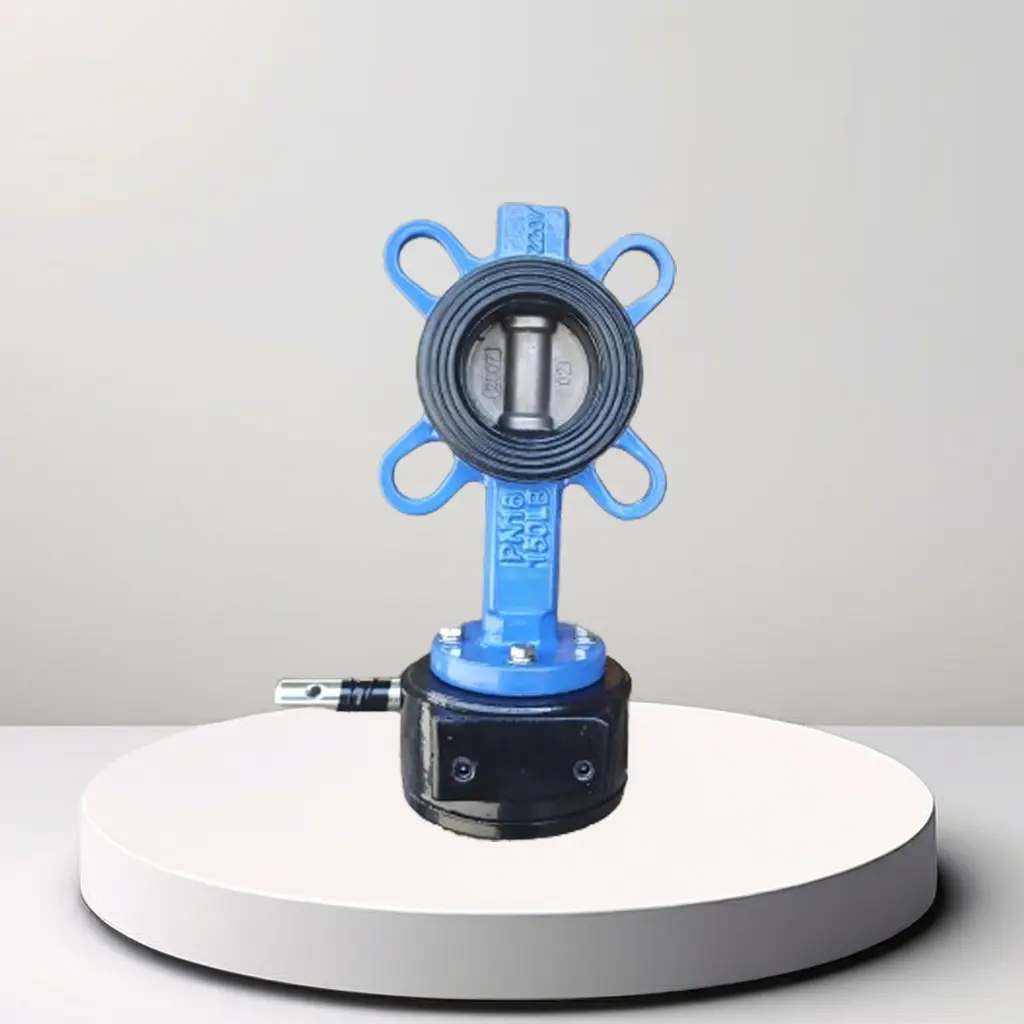

Product Description

PTFE Disc PTFE Seat DI Body Wafer Butterfly Valve is a high-level corrosion-resistant pipeline valve, commonly used in chemical, pharmaceutical, food and other demanding industries. The following is a detailed introduction to this butterfly valve:

1. Main components

PTFE Disc:

PTFE (polytetrafluoroethylene): PTFE is a high-performance plastic material with excellent chemical resistance, high temperature resistance and low friction coefficient. Using PTFE as the valve disc material can effectively resist corrosive media such as strong acids and alkalis.

PTFE Seat:

PTFE seat provides excellent sealing performance, ensuring that the valve is leak-free when closed. The self-lubrication and flexibility of PTFE material also help to extend the service life of the valve seat.

DI Body:

The valve body is made of ductile iron (DI), which has high strength and toughness and can withstand high pressure and mechanical stress. At the same time, ductile iron also has certain corrosion resistance and is suitable for most industrial environments.

Wafer Type:

The design of the wafer butterfly valve allows it to be easily installed between two flanges. The valve is fixed in the pipeline by bolts, which simplifies the installation and maintenance process.

2. Working Principle

The PTFE valve plate PTFE valve seat DI body wafer butterfly valve controls the flow of fluid by rotating the valve stem to drive the valve plate to rotate. The PTFE material between the valve plate and the valve seat provides reliable sealing performance, which effectively blocks the flow of fluid when the valve is closed.

3. Advantages

Corrosion resistance: The valve plate and valve seat of PTFE material can resist the corrosion of most chemical media and are suitable for various harsh working environments.

High sealing: The PTFE valve seat provides excellent sealing performance, ensuring no leakage, and is suitable for working conditions with strict sealing requirements.

Easy operation: The wafer design and lightweight materials make the valve installation and operation easier.

Long life: Corrosion-resistant materials and high-strength valve bodies extend the service life of the valve and reduce the frequency of maintenance and replacement.

4. Application scenarios

PTFE disc PTFE seat DI body wafer butterfly valve is widely used in the following fields:

Chemical industry: used for pipeline systems handling corrosive chemicals.

Pharmaceutical industry: used to control the flow of high-purity and corrosive media in pharmaceutical production.

Food industry: due to the corrosion resistance and non-toxicity of PTFE materials, it is suitable for food processing pipeline systems.

Water treatment: used to treat sewage and wastewater containing corrosive substances.

5. Installation and maintenance

Installation: clamp the valve between the pipe flanges and fix it with bolts. The wafer design makes the installation process simple and quick.

Regular inspection: regularly check the status of the valve disc and valve seat to ensure that they are not worn or corroded and maintain good sealing performance.

Maintenance: Due to the wear resistance and self-lubricating properties of PTFE materials, the valve has low maintenance requirements, but it still needs to be lubricated and cleaned regularly to ensure long-term stable operation.

6. Conclusion

PTFE disc PTFE seat DI body wafer butterfly valve is a highly corrosion-resistant and excellent sealing valve, especially suitable for industrial environments handling corrosive media. With its compact structure, easy operation and long service life, it is an ideal choice for fluid control in chemical, pharmaceutical, food and other industries.