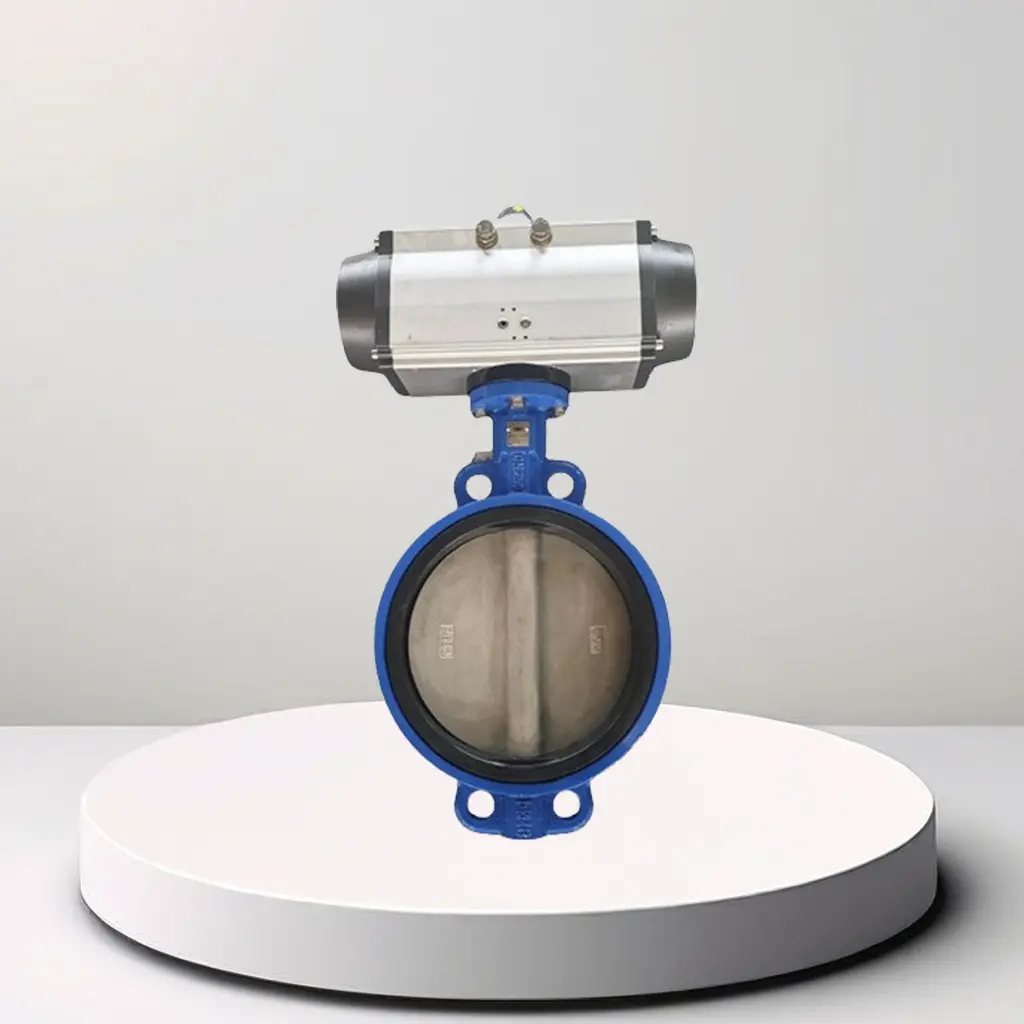

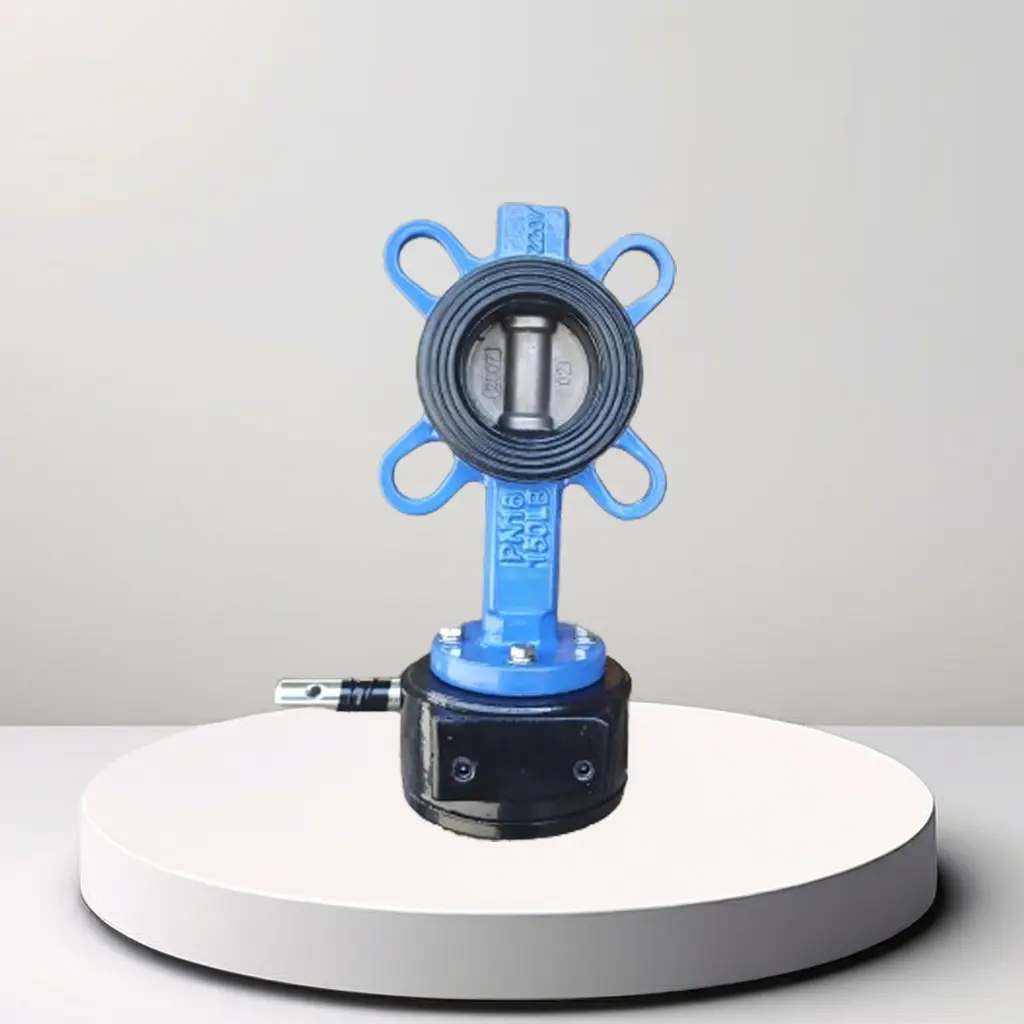

Product Description

The Worm Gear PTFE Seat Stainless Steel Butterfly Valve is a high-performance valve widely used in various industrial applications. Here's a detailed introduction:

1. Construction Materials:

- Body Material: The valve body is constructed from stainless steel, providing excellent resistance to corrosion, high temperatures, and wear. Stainless steel is known for its durability and is ideal for use in harsh environments.

- Seat Material: The seat of the valve is made from PTFE (polytetrafluoroethylene), a synthetic fluoropolymer known for its non-reactivity, high chemical resistance, and low friction. PTFE seats provide a tight seal, minimizing the risk of leaks and making the valve suitable for handling corrosive or sensitive fluids.

2. Design and Operation:

- Worm Gear Mechanism: The valve is operated using a worm gear, which consists of a worm (a gear in the form of a screw) that meshes with a worm wheel. This mechanism allows for precise control of the valve's position, enabling gradual opening and closing. The worm gear design also requires less force to operate the valve, making it easier to handle in various applications.

- Butterfly Valve Design: The valve's disc, located in the center of the pipe, rotates on an axis perpendicular to the flow. When the disc is turned, it either blocks or allows fluid to pass through, controlling the flow within the pipeline. The butterfly design is compact, lightweight, and provides a quick shut-off.

3. Applications:

- Chemical Processing: Due to its resistance to a wide range of chemicals, this valve is commonly used in chemical processing plants where exposure to corrosive substances is frequent.

- Water Treatment: The stainless steel body and PTFE seat make the valve suitable for use in water treatment facilities, where it can handle both clean and contaminated water without corroding.

- Food and Beverage Industry: The valve's materials are safe for use in the food and beverage industry, where hygiene and chemical resistance are critical. The PTFE seat ensures that there is no contamination of the processed materials.

- Pharmaceuticals: In pharmaceutical manufacturing, where purity and cleanliness are paramount, this valve is ideal due to its non-reactive and easy-to-clean materials.

4. Advantages:

- Corrosion Resistance: The stainless steel body combined with the PTFE seat provides superior resistance to corrosion, extending the valve's lifespan even in aggressive environments.

- Leak Tightness: The PTFE seat ensures a tight seal, reducing the risk of leaks and enhancing the safety and efficiency of the system.

- Ease of Operation: The worm gear mechanism makes the valve easy to operate, allowing for precise flow control with minimal effort.

- Durability: Stainless steel construction offers high mechanical strength and durability, making the valve reliable in demanding applications.

- Low Maintenance: The valve's design and materials reduce the need for frequent maintenance, minimizing downtime and operational costs.

5. Installation and Maintenance:

- Installation: This valve is typically installed between two flanges in a piping system. It can be installed in both horizontal and vertical positions, depending on the specific application requirements.

- Maintenance: Routine maintenance involves checking the condition of the PTFE seat and ensuring that the worm gear mechanism operates smoothly. Due to its robust design, the valve requires minimal maintenance compared to other types of valves.

In summary, the Worm Gear PTFE Seat Stainless Steel Butterfly Valve is a versatile and reliable choice for controlling the flow of fluids in various industrial sectors, offering a combination of chemical resistance, durability, and ease of operation.