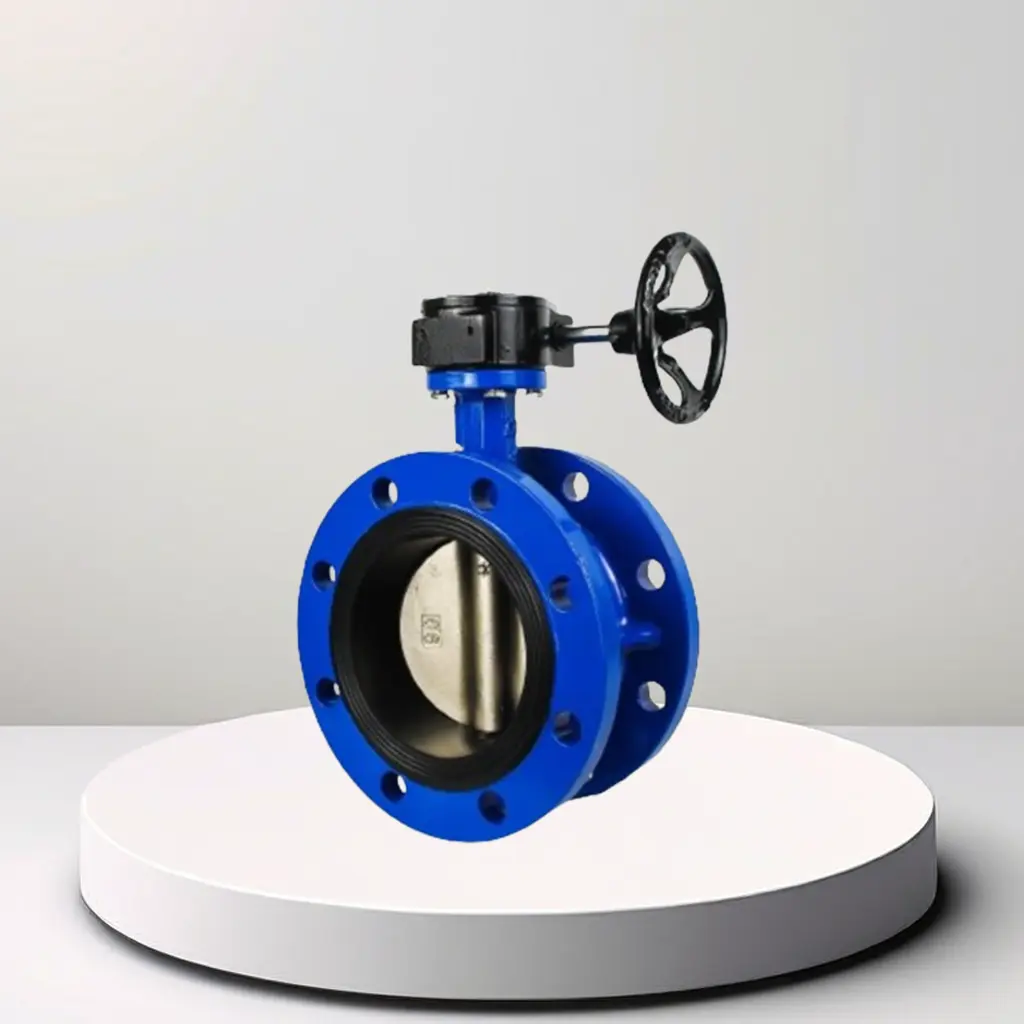

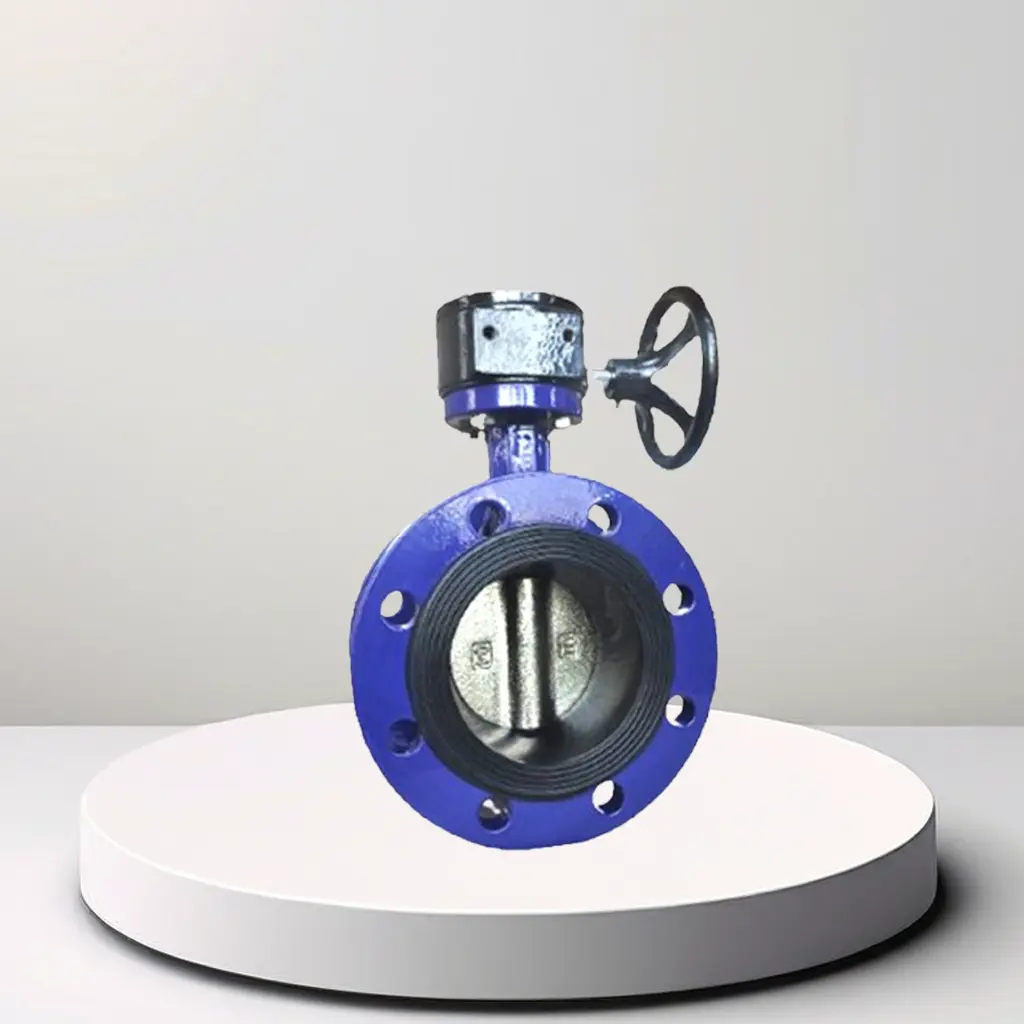

Product Description

The gear operated flange butterfly valve is a common industrial valve widely used in fluid control systems. It drives the butterfly plate to rotate through the gearbox operator to regulate or cut off the flow of fluid. The following is a detailed introduction to the gear operated flange butterfly valve:

1. Main components

Gearbox Operator:

Mechanism: The gearbox is operated by a handwheel or handle, and uses a gear transmission mechanism to drive the valve stem and butterfly plate to rotate. The gearbox operator can provide a large torque, making the operation more labor-saving, especially suitable for large-diameter and high-pressure valves.

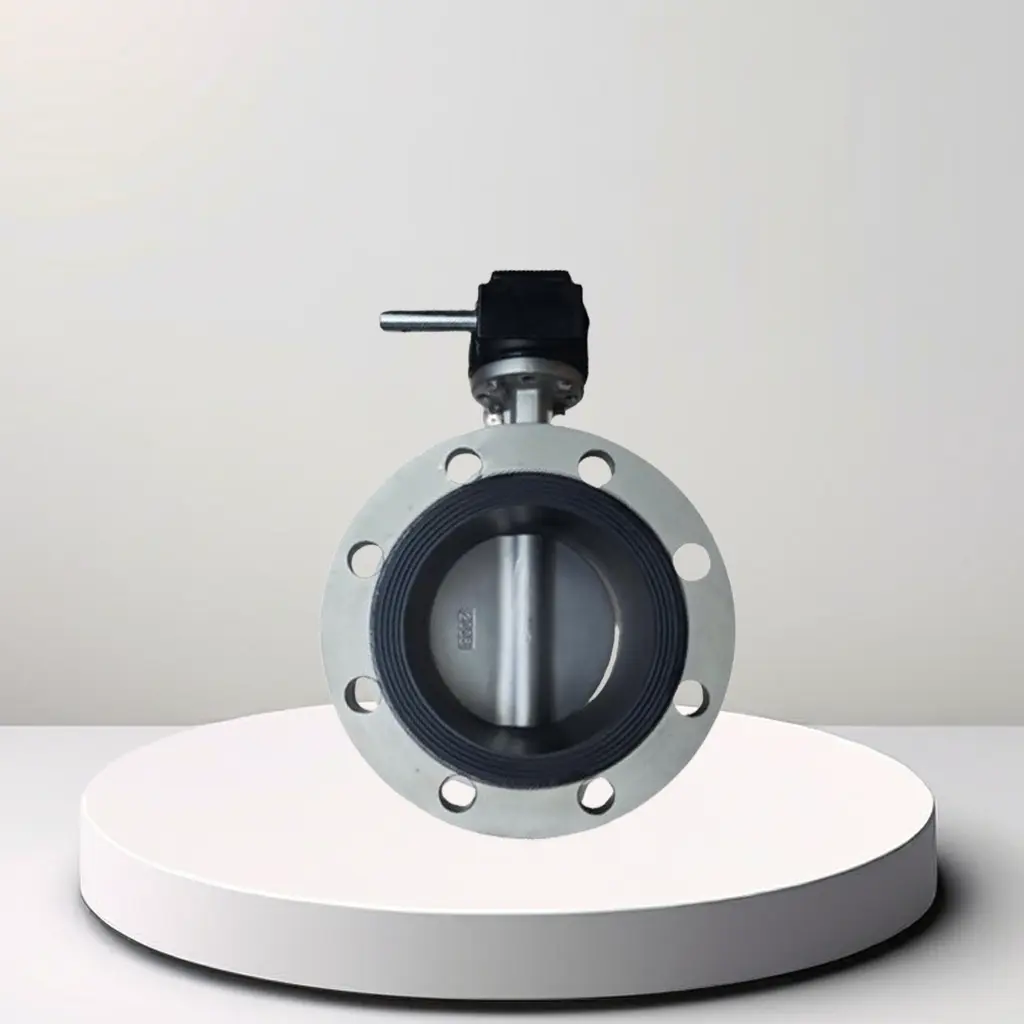

Valve Body:

Material: The valve body can be made of different materials, such as cast iron, ductile iron, carbon steel, stainless steel, etc. The specific material selection depends on the application environment and the type of medium.

Disc:

Material: The butterfly plate can be made of stainless steel, carbon steel or other corrosion-resistant materials to ensure good durability and sealing performance in various media.

Seat:

Material: The valve seat material is usually rubber, PTFE (polytetrafluoroethylene), etc., providing excellent sealing performance and chemical corrosion resistance.

Flanged Connection:

Flanged design: Flange butterfly valves are installed in the pipeline system through flange connection, providing a firm connection and reliable sealing. Flange standards can be ANSI, DIN, JIS, etc., selected according to the area of use and standards.

2. Working principle

The gear operated flange butterfly valve drives the gear transmission mechanism by rotating the handwheel or handle of the gearbox to rotate the valve stem and butterfly plate. The butterfly plate rotates 90 degrees in the valve body to open and close the valve. A seal is formed between the butterfly plate and the valve seat to control the flow of the fluid.

3. Advantages

Easy operation: The gear operating mechanism provides a large operating torque, making the operation more labor-saving and precise, suitable for large-diameter and high-pressure valves.

High sealing: The close fit between the butterfly plate and the valve seat provides good sealing performance and reduces leakage.

Compact structure: The flange butterfly valve has a compact structure and occupies a small space, which is suitable for installation environments with limited space.

Wide range of application: It is suitable for a variety of media, including water, gas, oil, chemicals, etc., and is widely used in various industrial fields.

Easy maintenance: The gear operator and flange connection design make the installation, disassembly and maintenance of the valve relatively simple.

4. Application Scenarios

The gear operated flange butterfly valve is widely used in the following fields:

Water treatment: used for fluid control and regulation in tap water and sewage treatment systems.

Oil and gas: used for fluid cutoff and regulation in oil and gas pipelines.

Chemical industry: handles various corrosive chemicals to ensure the safe operation of pipeline systems.

Power industry: used for fluid control in power plant cooling water, boiler feed water and other systems.

Heating, ventilation and air conditioning (HVAC): used for air and liquid flow control in heating, ventilation and air conditioning systems.

5. Installation and maintenance

Installation: Install the valve between the pipe flanges and fix it with bolts. Make sure the valve is coaxial with the pipe to ensure good sealing performance.

Regular inspection: Regularly check the lubrication and operating flexibility of the gear operator to ensure that the valve is free of wear and corrosion.

Maintenance: Clean the inside and outside of the valve regularly and check the sealing of the valve seat and butterfly plate. Replace the valve seat and seal when necessary.

Conclusion

The gear operated flange butterfly valve is a valve with excellent performance and easy operation, suitable for a variety of industrial fluid control applications. Its high sealing performance, compact structure and easy maintenance make it an ideal choice for fluid control in chemical, petroleum, natural gas, water treatment and other industries.