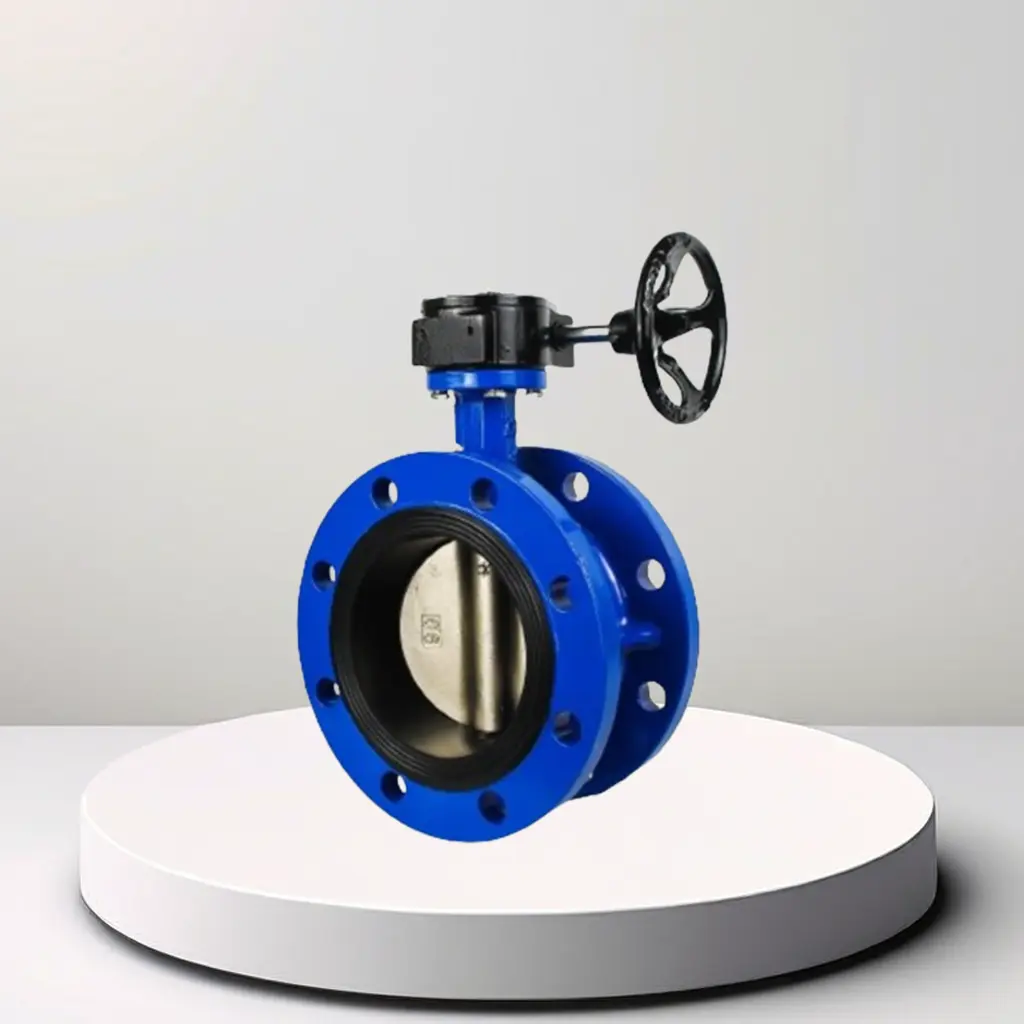

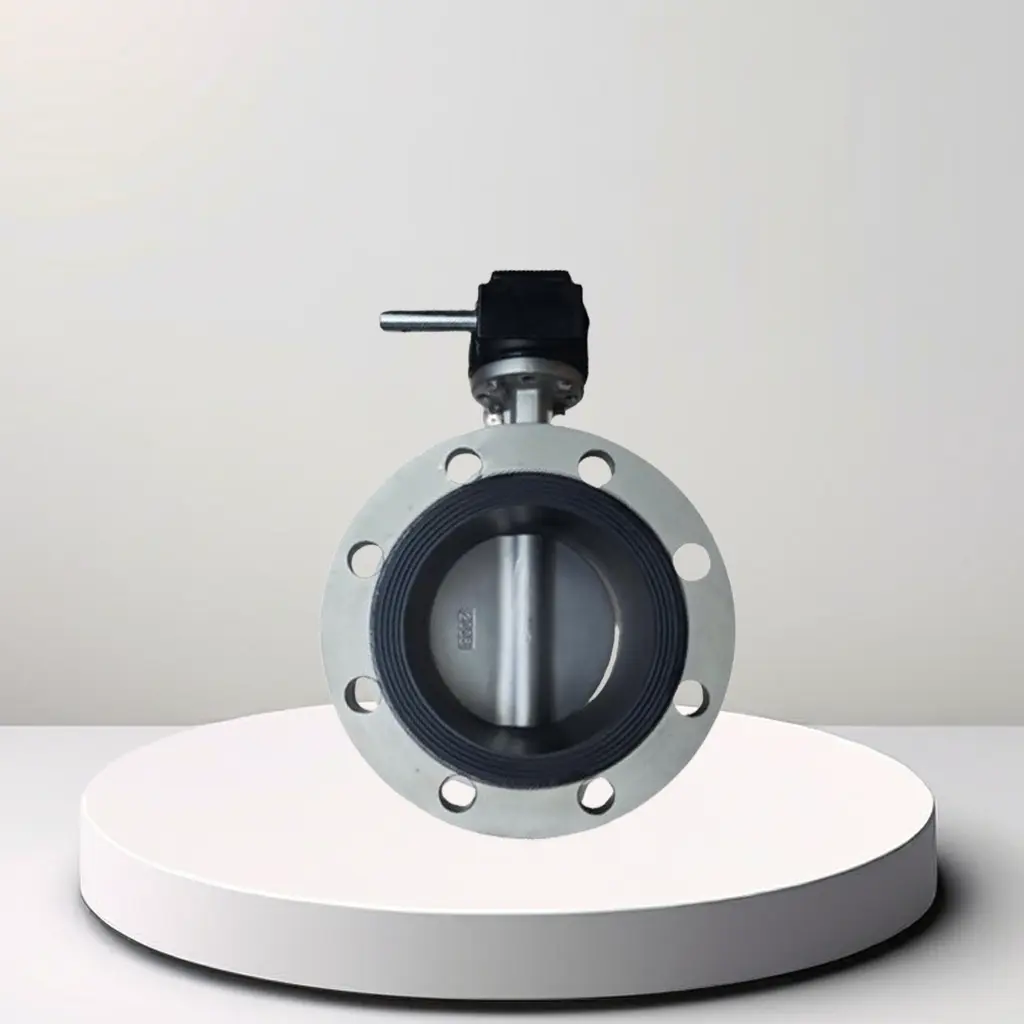

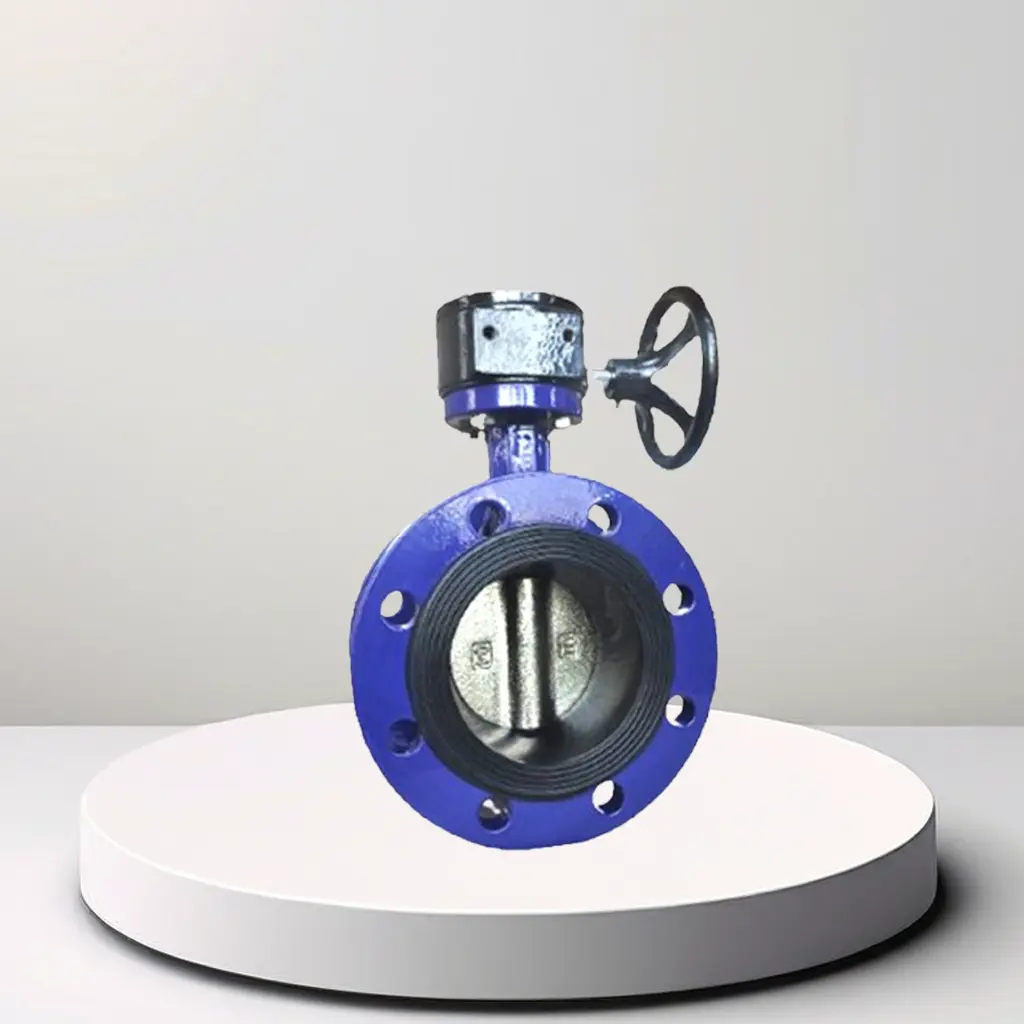

Product Description

A stainless steel flange butterfly valve is a critical component in various industrial piping systems, designed to control the flow of liquids, gases, and slurries. Here’s a detailed introduction to its features, working principles, applications, and benefits:

Features:

1. Material: Made from stainless steel, typically grades like 304, 316, or 316L, which offer high corrosion resistance, durability, and strength.

2. Design:

- Butterfly Disc: The central component that rotates to open or close the valve.

- Shaft: Connects the actuator or handle to the butterfly disc, enabling rotation.

- Seat: Provides a seal between the disc and valve body, often made from elastomeric materials for tight sealing.

- Flanges: Standardized flanges (e.g., ANSI, DIN) on either side for easy installation and removal in piping systems.

3. Actuation: Can be manually operated with a lever or gear, or automated with electric, pneumatic, or hydraulic actuators.

4. Seal Design: Ensures minimal leakage, with options for soft sealing or metal-to-metal sealing depending on the application requirements.

Working Principle:

The valve operates by rotating the butterfly disc, typically by 90 degrees. When the disc is parallel to the flow, the valve is fully open, allowing maximum flow. When the disc is perpendicular to the flow, the valve is closed, stopping the flow. Intermediate positions of the disc allow for flow regulation.

Applications:

1. Water Treatment Plants: Used for isolating and regulating water flow.

2. Food and Beverage Industry: Suitable for sanitary applications due to its corrosion resistance and ease of cleaning.

3. Chemical Processing: Handles aggressive chemicals without corroding.

4. Pharmaceutical Industry: Ensures high purity and cleanliness standards.

5. Oil and Gas: Used in refining, transporting, and storing hydrocarbons.

6. HVAC Systems: Controls the flow of air and fluids in heating, ventilation, and air conditioning systems.

Benefits:

1. Corrosion Resistance: Stainless steel construction offers excellent resistance to corrosion and oxidation, even in harsh environments.

2. Durability: High mechanical strength and resistance to wear and tear, ensuring a long service life.

3. Ease of Maintenance: Flanged design allows for easy removal, inspection, and maintenance.

4. Compact Design: Takes up less space compared to other types of valves, making it suitable for applications with space constraints.

5. Cost-Effective: Lower cost and simpler design compared to other valve types like ball or gate valves.

6. Versatility: Suitable for a wide range of fluids, including liquids, gases, and slurries, across various industries.

Installation and Maintenance:

- Installation: Ensure that the flanges match the pipeline flanges and use appropriate gaskets to prevent leaks. Align the valve correctly to avoid stress on the piping system.

- Maintenance: Regular inspection of the seat and disc for wear and tear. Lubrication of the shaft and actuator mechanism to ensure smooth operation.

By combining reliability, versatility, and ease of use, stainless steel flange butterfly valves are an essential component in modern industrial and commercial piping systems.