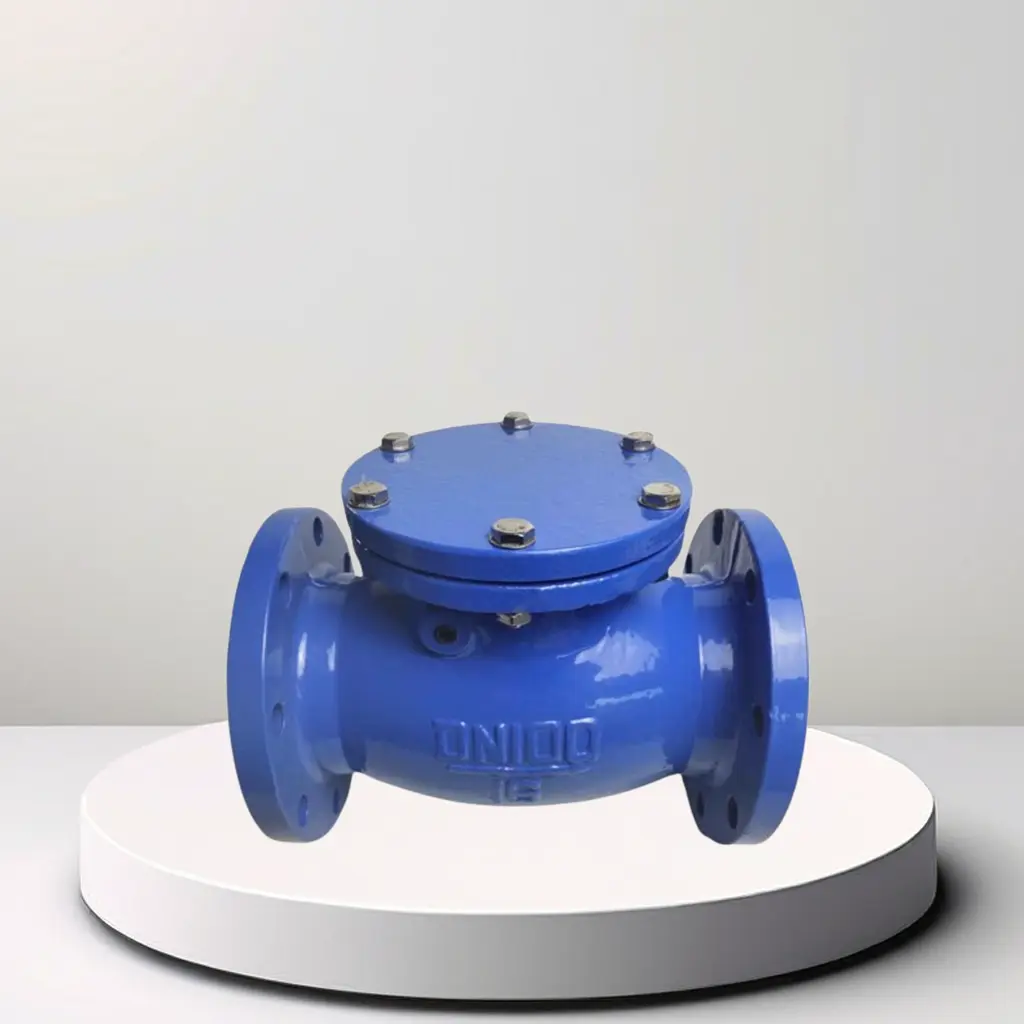

Product Description

A swing check valve is a type of check valve used to control the flow of fluids in pipelines. Here's a detailed description:

Construction and Design

1. Body: The body of a swing check valve is typically made of materials such as cast iron, carbon steel, stainless steel, or bronze. It provides the housing for the valve components and ensures structural integrity.

2. Disc: The valve has a hinged disc, which swings freely on a pivot or hinge located at the top of the valve body. The disc is designed to swing away from the seat to allow forward flow and to return to the seat to prevent reverse flow.

3. Seat: The seat is a machined surface against which the disc seals when the valve is closed. It prevents fluid from flowing backward when the valve is in the closed position.

4. Hinge/Pivot Mechanism: The disc is attached to the valve body via a hinge or pivot mechanism, allowing it to swing freely in response to changes in fluid flow direction.

Working Principle

- Forward Flow: When fluid flows in the desired direction (from the inlet to the outlet), the pressure of the fluid pushes the disc away from the seat, allowing the fluid to pass through the valve.

- Backflow Prevention: If the flow reverses or stops, the disc swings back to the closed position due to gravity and fluid pressure, sealing against the seat and preventing backflow.

Features

1. Automatic Operation: Swing check valves operate automatically based on changes in fluid flow direction and pressure, requiring no external actuation.

2. Low Pressure Drop: When open, swing check valves offer minimal resistance to flow, resulting in a low pressure drop across the valve.

3. Full Flow Area: The design of swing check valves typically allows for a full flow area, maximizing flow capacity and reducing head loss.

4. Versatility: Swing check valves are suitable for a wide range of fluid types, temperatures, and pressures.

5. Maintenance: These valves generally require minimal maintenance due to their simple design and few moving parts.

Applications

- Water Supply and Distribution: Used in municipal water supply systems, irrigation systems, and water treatment plants.

- Wastewater Management: Employed in sewage treatment plants and drainage systems to prevent backflow.

- Oil and Gas Industry: Used in pipelines for crude oil, natural gas, and petroleum products to prevent reverse flow and maintain system integrity.

- Chemical Processing: Utilized in chemical plants to control the flow of various chemicals and process fluids.

- HVAC Systems: Incorporated into heating, ventilation, and air conditioning systems to prevent reverse flow in cooling and heating circuits.

Advantages

- Reliable Backflow Prevention: Swing check valves effectively prevent backflow, protecting equipment and maintaining system efficiency.

- Simple Design: The straightforward design of swing check valves makes them easy to install, operate, and maintain.

- Versatility: Suitable for a wide range of fluid applications and operating conditions.

- Cost-Effective: Swing check valves are generally cost-effective solutions for backflow prevention.

Swing check valves are essential components in fluid systems where backflow prevention is crucial. Their automatic operation, low pressure drop, and versatility make them suitable for various industrial, municipal, and residential applications, ensuring efficient and reliable flow control。