Product Description

Introduction

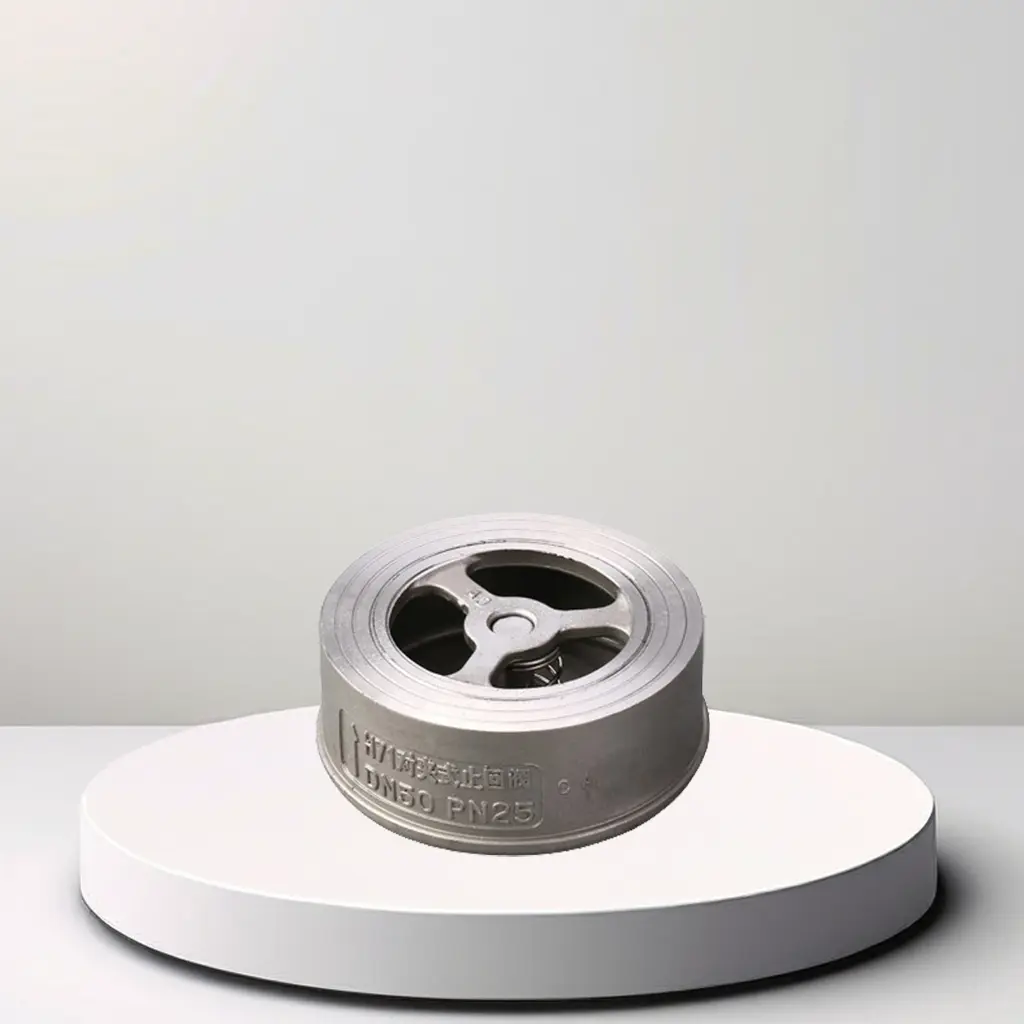

The DI Body Wafer Check Valve is a robust and reliable valve designed to prevent reverse flow in piping systems. Constructed from ductile iron (DI), this wafer-type check valve is widely used in water supply, wastewater treatment, HVAC systems, and various industrial applications. It is known for its durability, efficient flow control, and ease of installation.

Key Features

1. Ductile Iron (DI) Body:

- Material: The valve body is made from ductile iron, also known as nodular cast iron. Ductile iron is renowned for its high tensile strength, excellent corrosion resistance, and shock resistance.

- Durability: The use of ductile iron ensures that the valve can withstand high pressures and harsh conditions, extending the valve's service life.

2. Wafer Type Design:

- Structure: The wafer design features a thin, flat body that fits between two flanges in a pipeline. This design allows for easy installation and removal without disturbing the existing piping system.

- Space Efficiency: The wafer design is compact, making it suitable for applications where space is limited.

3. Check Valve Mechanism:

- Operation: The valve uses a disc or flap that opens to allow flow in one direction and closes to prevent reverse flow. The disc is typically spring-loaded to ensure quick and reliable operation.

- Self-Regulating: The check valve automatically opens and closes based on the fluid flow direction and pressure, requiring no external control.

4. Flow Control:

- Unidirectional Flow: The valve ensures that fluid flows only in one direction, preventing backflow that could cause system damage or operational issues.

- Smooth Operation: The design allows for minimal pressure loss and smooth flow characteristics, which contributes to the efficiency of the overall system.

5. Corrosion Protection:

- Coating: The valve body is often coated with an epoxy resin or similar protective coating to enhance corrosion resistance, especially for water and wastewater applications.

Technical Specifications

- Size Range: Available in various sizes, typically from 2 inches (50 mm) to 24 inches (600 mm), though sizes outside this range may be available upon request.

- Pressure Rating: Designed to handle different pressure ratings, commonly up to 150 PSI (10.3 bar) for standard applications. Higher pressure ratings can be offered for specific needs.

- Temperature Range: Operates effectively in temperatures ranging from -10°C to 80°C (14°F to 176°F), depending on the materials used and the design specifications.

- End Connections: Fits between flanges with a wafer design, compatible with ANSI, DIN, and JIS standards for easy integration into existing pipelines.

Applications

- Water Supply Systems: Used in municipal and industrial water distribution systems to prevent backflow and protect against potential contamination.

- Wastewater Treatment: Applied in wastewater treatment plants to control the flow of effluent and prevent backflow into the treatment processes.

- HVAC Systems: Integrated into heating, ventilation, and air conditioning systems for fluid control and to maintain system integrity.

- Fire Protection Systems: Employed in fire protection systems to ensure that water or other fire-suppressing agents flow in the correct direction.

- Industrial Processes: Utilized in various industrial processes where controlled fluid flow and backflow prevention are required.

Advantages

1. Reliable Backflow Prevention: Ensures that fluid flows in only one direction, protecting the system from backflow and potential damage.

2. Durable Construction: Ductile iron body provides high strength and resistance to wear and corrosion.

3. Compact and Space-Efficient: The wafer design is slim and easy to install between flanges, saving space and reducing installation time.

4. Corrosion Resistance: Protective coatings and the inherent properties of ductile iron offer excellent resistance to corrosion.

5. Easy Maintenance: The wafer type design allows for straightforward maintenance, with the ability to remove or replace the valve without disassembling the pipeline.

6. Cost-Effective: Generally, wafer-type check valves are less expensive and require less space compared to other types of check valves.

Disadvantages

1. Pressure Drop: There may be a slight pressure drop across the valve due to the disc mechanism and flow dynamics.

2. Limited Temperature Range: Not suitable for very high or low-temperature applications beyond the standard temperature range.

Conclusion

The DI Body Wafer Check Valve is a versatile and efficient solution for managing fluid flow in various systems. Its durable ductile iron construction, space-saving wafer design, and reliable check valve mechanism make it an ideal choice for many industrial and municipal applications. Whether for water supply, wastewater treatment, or HVAC systems, this valve offers dependable performance and ease of use.