Product Description

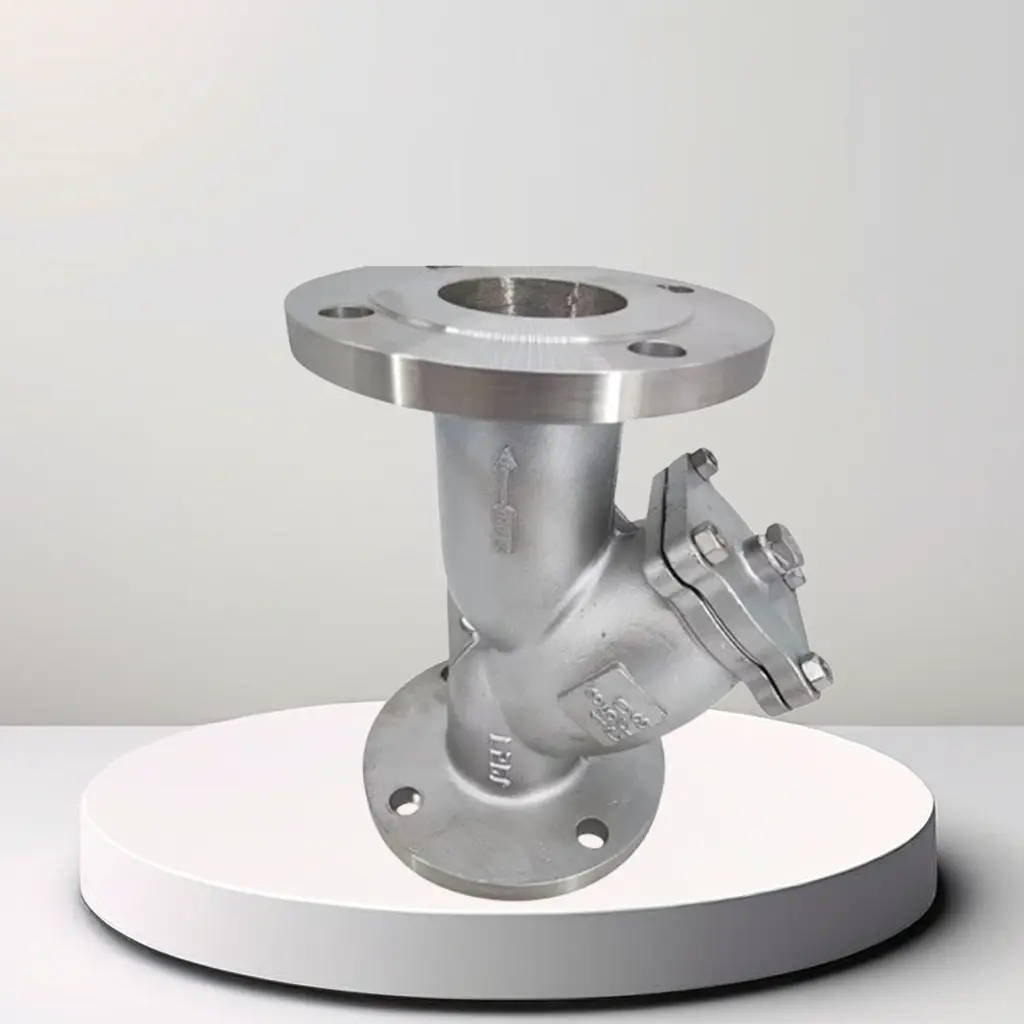

A DIN DI Material Y-Strainer is a specific type of Y-strainer designed and manufactured according to DIN (Deutsches Institut für Normung) standards, which are widely recognized and used in Europe. The "DI" refers to ductile iron, a material known for its strength, durability, and resistance to impact and corrosion. This Y-strainer is used to filter out debris from fluids in various pipeline systems, ensuring the protection and longevity of downstream equipment.

Components and Design:

1. Body: The main housing of the Y-strainer is made from ductile iron, offering high strength and durability. Ductile iron is more resistant to impact and fatigue compared to traditional cast iron, making it ideal for high-pressure and high-stress applications.

2. Screen (Mesh or Perforated): The internal filtering element is made from stainless steel or a similar corrosion-resistant material. It traps debris and particulates, preventing them from flowing downstream. The screen's mesh size or perforation pattern is selected based on the specific filtration requirements of the system.

3. Cover (Blow-off Cap or Plug): Located at the bottom of the Y-leg, the cover allows for easy access to the screen for maintenance. This cover can be removed to clean or replace the screen. Some designs include a blow-off valve that enables flushing out debris without removing the cover, enhancing convenience and efficiency.

4. Flanges or Threaded Ends: The connection points for integrating the Y-strainer into the pipeline system. These can be flanged or threaded, providing flexibility in installation to match existing pipeline configurations.

5. Gasket and Bolts: The cover is sealed with a gasket to prevent leaks and is secured with bolts, ensuring a tight and reliable seal.

Working Principle:

1. Fluid Entry: Fluid enters the Y-strainer through the inlet and is directed towards the screen.

2. Debris Trapping: As the fluid passes through the screen, debris and particulates are trapped, while the clean fluid continues through the outlet. The angled design helps direct debris into the Y-leg, minimizing flow resistance and pressure drop.

3. Debris Removal: Periodically, the strainer needs to be cleaned to maintain efficiency. The cover can be removed to access the screen, or the blow-off valve can be used to flush out the debris.

Advantages:

1. Compliance with DIN Standards: Ensures high quality, reliability, and compatibility with other DIN-compliant components.

2. Durability: Made from ductile iron, the Y-strainer offers excellent resistance to mechanical stress, impact, and corrosion, leading to a longer service life.

3. Efficient Filtration: The well-designed screen effectively traps debris, protecting downstream equipment and maintaining system efficiency.

4. Easy Maintenance: The design allows for straightforward cleaning and screen replacement, with options for blow-off valves enhancing ease of use.

5. Versatility: Suitable for various fluids, including water, oil, and gas, making it applicable in numerous industries.

Applications:

1. Water Treatment: Ensures clean water supply by filtering out debris, protecting pumps, valves, and other equipment.

2. Oil and Gas: Filters contaminants in pipelines, safeguarding sensitive equipment and maintaining smooth operations.

3. Chemical Processing: Prevents clogging and damage to process equipment by filtering particulates from chemicals and process fluids.

4. HVAC Systems: Maintains clean water or steam supply, protecting system components and enhancing efficiency.

5. Food and Beverage: Ensures sanitary conditions by removing particulates from water and other process fluids.

Installation and Maintenance:

1. Orientation: Install with the leg of the Y pointing downwards to collect debris effectively and allow for easy cleaning.

2. Access: Ensure sufficient space around the strainer for removing the cover and accessing the screen.

3. Material Compatibility: Verify that the strainer materials are compatible with the fluid and operating environment to prevent corrosion and wear.

4. Regular Inspection: Periodically check the screen for clogging and clean or replace it as necessary to maintain optimal performance.

In summary, a DIN DI Material Y-Strainer is a robust and efficient filtration device, designed to meet high standards of quality and reliability. Its durable construction and effective filtration capabilities make it a valuable component in various industrial and commercial applications.