Product Description

Stainless Steel Material Y-Strainer: Detailed Description

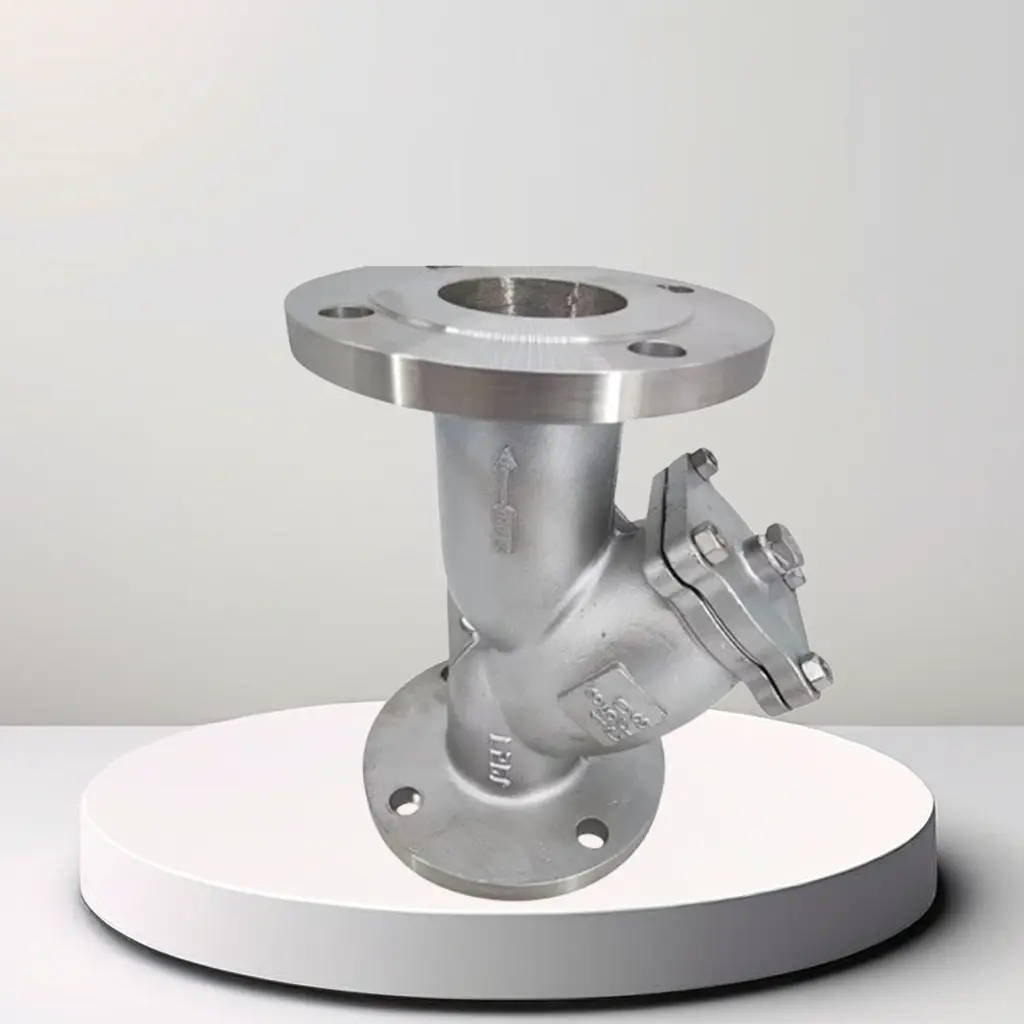

A stainless steel material Y-strainer is a robust filtration device used in piping systems to remove solids and debris from fluid flows. It is constructed primarily from stainless steel, which is chosen for its exceptional corrosion resistance, durability, and suitability for a wide range of industrial applications. Here's a comprehensive overview of its components, working principle, advantages, applications, and installation considerations:

Components and Design:

1. Body: The main housing of the Y-strainer, typically fabricated from stainless steel (grades such as 304 or 316), which provides excellent resistance to corrosion, high temperatures, and various chemicals. Stainless steel ensures longevity and reliability in demanding environments.

2. Screen (Mesh or Perforated): The internal filter element, also made from stainless steel, features a mesh or perforated pattern. This screen effectively traps solid particles and debris while allowing fluid to pass through without significant pressure drop. The mesh size or perforation diameter is selected based on the application's filtration requirements.

3. Cover (Blow-off Cap or Plug): Positioned at the bottom of the Y-leg, the cover allows easy access to the screen for maintenance. It can be removed to clean or replace the screen periodically. Some designs include a blow-off valve to facilitate debris removal without dismantling the strainer, enhancing convenience and reducing downtime.

4. Connections: Equipped with threaded ends or flanges for straightforward installation into the pipeline system. The choice between threaded or flanged connections depends on the specific installation requirements and system standards.

Working Principle:

1. Fluid Flow: Fluid enters the Y-strainer through the inlet and is directed towards the screen.

2. Debris Filtration: As the fluid passes through the mesh or perforated screen, solid particles and debris larger than the screen openings are captured. Clean fluid continues through the outlet, while contaminants accumulate inside the Y-leg of the strainer.

3. Maintenance: Periodically, the strainer requires maintenance to remove accumulated debris and ensure optimal filtration efficiency. The cover is removed, and the screen is cleaned or replaced as needed, maintaining peak performance of the filtration system.

Advantages:

1. Corrosion Resistance: Stainless steel provides exceptional resistance to corrosion, ensuring long-term reliability and minimal maintenance in corrosive environments, such as marine, chemical processing, and food processing industries.

2. Durability: Stainless steel is renowned for its strength and durability, capable of withstanding high pressures, temperatures, and mechanical stresses without compromising performance.

3. High Filtration Efficiency: The precise mesh or perforated screen effectively traps solid particles and debris, protecting downstream equipment and maintaining system integrity.

4. Versatility: Suitable for a wide range of fluids, including water, oils, gases, chemicals, and more, making it versatile across various industries and applications.

5. Sanitary Applications: Stainless steel Y-strainers meet sanitary standards required in industries like pharmaceuticals, food and beverage processing, and biotechnology, where cleanliness and sterility are paramount.

Applications:

1. Water Treatment: Used in municipal water systems, industrial water treatment plants, and HVAC systems to remove particulates and ensure clean water supply.

2. Oil and Gas Industry: Installed in pipelines and refineries to protect pumps, meters, and other equipment from debris, enhancing operational efficiency and reliability.

3. Chemical Processing: Essential for filtering chemicals and process fluids to prevent contamination and maintain product quality in manufacturing processes.

4. Food and Beverage: Ensures sanitary conditions by removing particles and contaminants from processing fluids, meeting hygiene standards in food processing facilities.

5. HVAC Systems: Filters circulating water or fluids in heating, ventilation, and air conditioning systems, preventing clogging and damage to system components.

Installation and Maintenance:

1. Orientation: Install the Y-strainer with the leg of the Y pointing downwards to facilitate effective debris collection and easy access for maintenance.

2. Material Compatibility: Verify that stainless steel grades used are compatible with the fluid and environmental conditions to ensure long-term performance and reliability.

3. Regular Inspection: Periodically inspect the screen for debris buildup and clean or replace it as necessary to maintain optimal filtration efficiency and system functionality.

4. Pressure and Temperature Ratings: Consider the operating conditions to select a stainless steel Y-strainer that meets the pressure and temperature requirements of the application.

In summary, a stainless steel material Y-strainer is a highly durable and efficient filtration solution, designed to protect equipment and maintain fluid system performance across a broad spectrum of industrial and commercial applications. Its corrosion resistance, longevity, and ease of maintenance make it a preferred choice for critical filtration needs in various industries worldwide.