Product Description

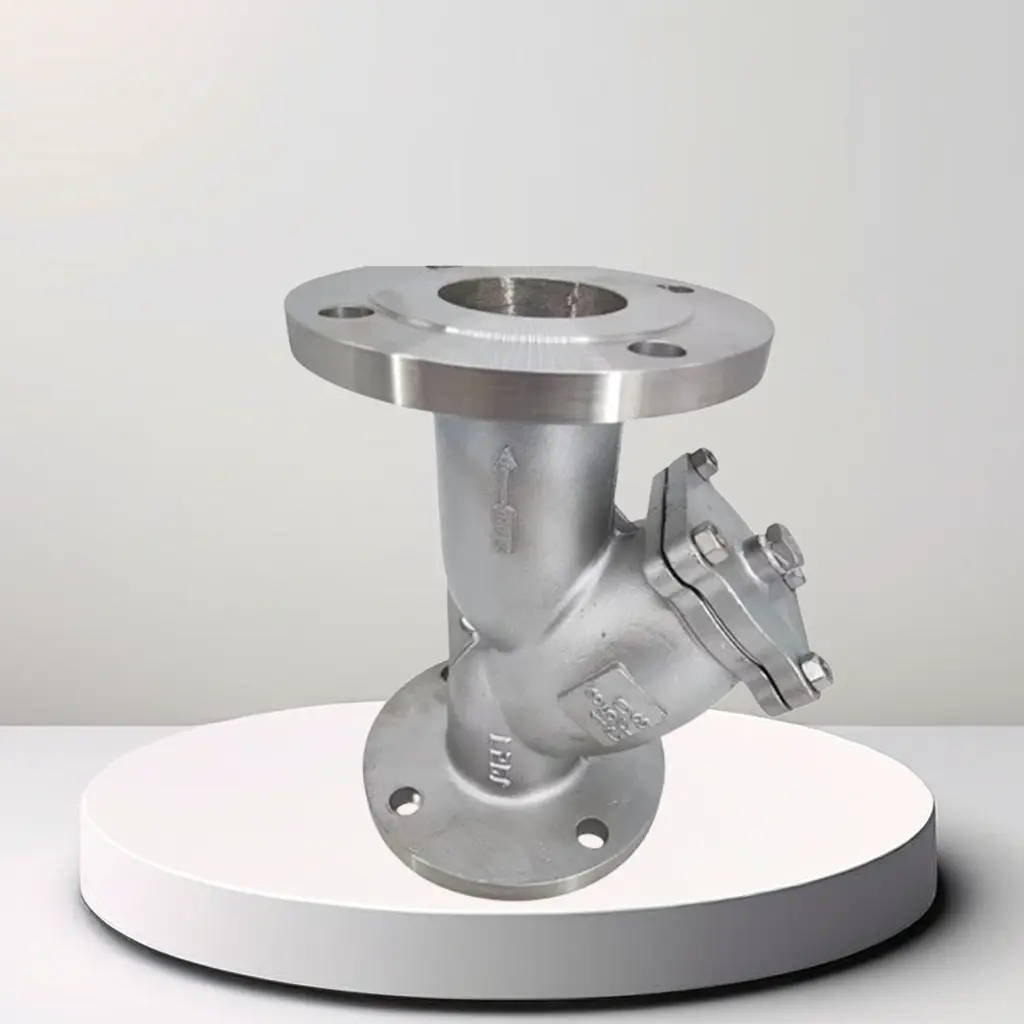

Detailed Description of UL Fire Protection Flange-Flange Ends Y-Strainer

The UL Fire Protection Flange-Flange Ends Y-Strainer is a critical component in fire protection systems, designed to ensure reliable operation and compliance with safety standards set by UL (Underwriters Laboratories). Here's a comprehensive overview of its components, design, working principle, advantages, applications, and installation considerations:

Components and Design:

1. Body: The main housing of the Y-strainer is typically constructed from durable materials such as ductile iron or stainless steel, chosen for their strength and corrosion resistance. The material used complies with UL standards for fire protection equipment.

2. Screen (Mesh or Perforated): The internal filter element is made from stainless steel or brass, featuring a fine mesh or perforated pattern. This screen effectively traps debris and particulates from the water flow, ensuring clean water supply to fire sprinkler systems.

3. Flange-Flange Ends: The Y-strainer is equipped with flange connections at both ends. These flanges facilitate secure and leak-proof installation into the fire protection pipeline system. The flange sizes and ratings comply with ANSI (American National Standards Institute) standards to ensure compatibility and safety.

4. Cover (Blow-off Cap or Plug): Positioned at the bottom of the Y-leg, the cover allows easy access to the screen for maintenance. It can be removed to clean or replace the screen periodically. Some designs include a blow-off valve for quick debris removal without dismantling the strainer.

Working Principle:

1. Fluid Flow: Water enters the Y-strainer through the inlet flange and is directed towards the mesh or perforated screen.

2. Debris Filtration: As water passes through the screen, solid particles and debris larger than the screen openings are captured and retained inside the Y-strainer.

3. Maintenance: Regular inspection and maintenance are essential to ensure the strainer operates effectively during emergencies. The cover is removed, and the screen is cleaned or replaced as needed to maintain optimal filtration efficiency.

Advantages:

1. UL Certification: The Y-strainer meets UL standards for fire protection equipment, ensuring it complies with rigorous safety and performance criteria.

2. Reliability: Designed to prevent debris from entering and potentially clogging fire sprinkler heads, ensuring the system remains operational during fire emergencies.

3. Corrosion Resistance: Constructed from materials that provide excellent corrosion resistance, suitable for long-term use in fire protection applications.

4. Ease of Installation: Flange connections at both ends simplify installation and ensure a secure, leak-free connection to the pipeline system.

5. Critical Component: Plays a crucial role in maintaining the reliability and effectiveness of fire protection systems, protecting property and lives in case of fire incidents.

Applications:

1. Commercial Buildings: Installed in fire protection systems of high-rise buildings, hospitals, schools, and other commercial facilities to ensure compliance with fire safety regulations.

2. Industrial Facilities: Used in manufacturing plants, warehouses, and industrial complexes where fire protection is critical to safeguarding operations and personnel.

3. Residential Buildings: Integrated into fire sprinkler systems in residential buildings and apartment complexes to provide reliable fire suppression capabilities.

Installation and Maintenance:

1. Orientation: Install the Y-strainer with the leg of the Y pointing downwards to facilitate effective debris collection and maintenance access.

2. Compatibility: Ensure compatibility of the strainer material with the water supply and environmental conditions to prevent corrosion and ensure long-term performance.

3. Regular Inspection: Schedule periodic inspections and maintenance to verify the strainer's condition, clean or replace the screen as needed, and ensure uninterrupted operation during emergencies.

4. Compliance: Verify compliance with local fire codes, regulations, and standards governing fire protection equipment installation and maintenance.

In summary, the UL Fire Protection Flange-Flange Ends Y-Strainer is a critical component in fire protection systems, designed and certified to ensure reliable operation, debris filtration, and compliance with stringent safety standards. Its robust construction, ease of maintenance, and essential role in fire safety make it indispensable in protecting properties and lives from fire hazards.