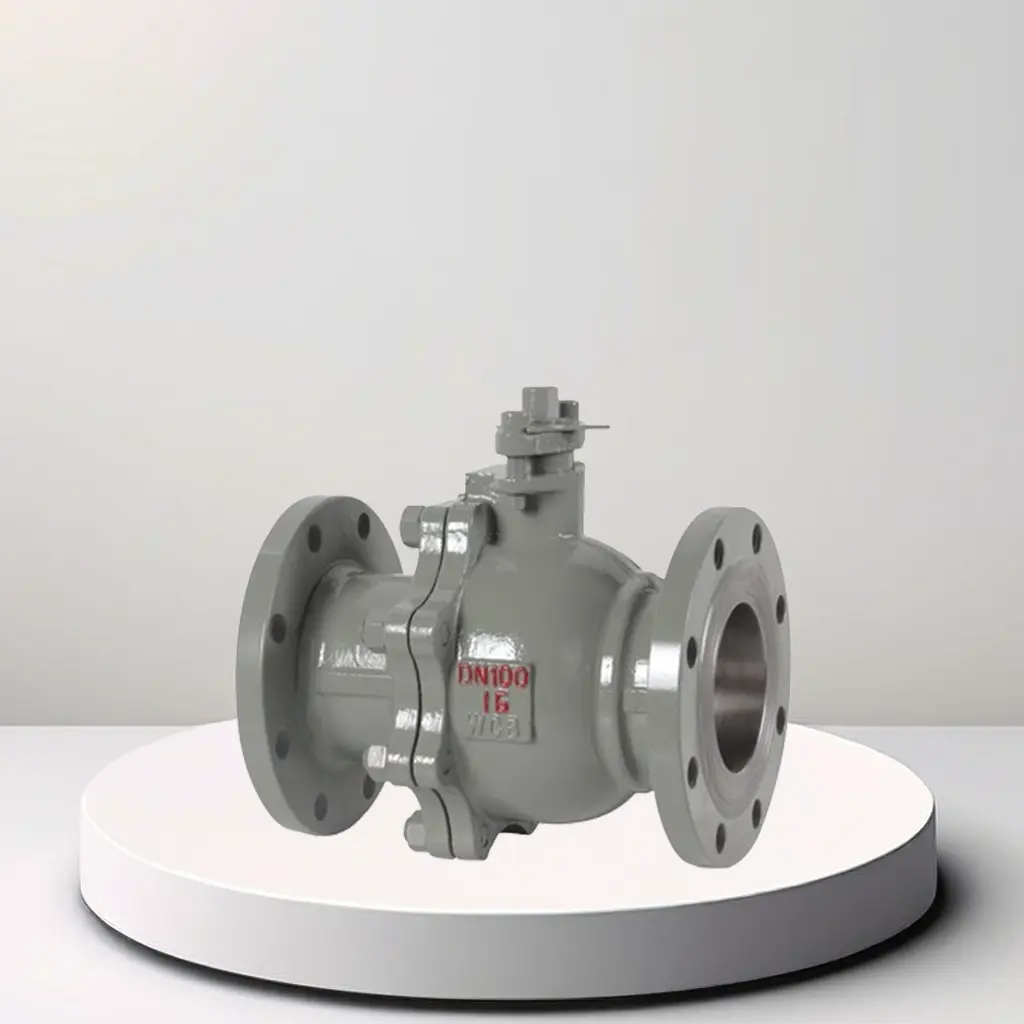

Product Description

A Carbon Steel Flange Ball Valve is a robust industrial valve designed for controlling the flow of fluids or gases in pipelines where high pressure and temperature conditions are common. Here’s a detailed description of its construction, operation, advantages, and applications:

Construction:

1. Valve Body: Made from carbon steel, which provides excellent strength and resistance to wear and corrosion. Carbon steel is chosen for its durability and suitability for high-pressure applications.

2. Ball: The valve features a spherical ball with a hole (bore) through its center. This ball is typically made from stainless steel or other materials depending on the specific application requirements.

3. Seats and Seals: The valve includes seats and seals made from materials such as PTFE (Polytetrafluoroethylene) or reinforced graphite, ensuring a tight seal and reliable operation over the valve's lifecycle.

4. Flanged Ends: The valve ends are equipped with flanges, which provide a secure and leak-proof connection to pipes or equipment in the pipeline system. Flanged connections facilitate easier installation and maintenance.

5. Actuation: Carbon steel flange ball valves can be manually operated via a hand lever or automated using electric or pneumatic actuators. Actuators allow for remote operation and integration into automated control systems.

Operation:

- Flow Control: Rotating the ball within the valve body controls the flow of fluids or gases. When the bore of the ball aligns with the pipeline, it allows for unrestricted flow (open position). Rotating the ball 90 degrees blocks the flow (closed position), providing precise control.

- High Pressure and Temperature: Designed to withstand high-pressure environments up to class ratings like ANSI 150, 300, 600, etc., and temperatures ranging from -29°C to 427°C (-20°F to 800°F).

Advantages:

- Strength and Durability: Carbon steel construction ensures the valve can withstand demanding industrial conditions, including corrosive environments and high temperatures.

- Reliable Sealing: The valve's design and materials provide a reliable seal, minimizing leakage even under high-pressure conditions.

- Versatility: Suitable for a wide range of applications including oil and gas, petrochemical, power generation, chemical processing, and industrial processes.

Applications:

- Oil and Gas Industry: Used in pipelines for flow control of crude oil, natural gas, and refined products.

- Chemical Processing: Handles corrosive chemicals and fluids safely and reliably.

- Power Generation: Controls steam and water flow in power plants and utilities.

- Industrial Processes: Suitable for various industrial applications requiring robust and reliable flow control solutions.

Installation and Maintenance:

- Flange Connections: Ensure proper alignment and bolt tightening according to specified torque values to prevent leaks.

- Regular Maintenance: Periodic inspection and lubrication of valve components ensure optimal performance and extend the valve's service life.

In summary, a Carbon Steel Flange Ball Valve is a durable and reliable choice for industrial applications where high-pressure and high-temperature conditions are present. Its robust construction, reliable sealing, and versatility make it essential for fluid control in critical industrial processes.