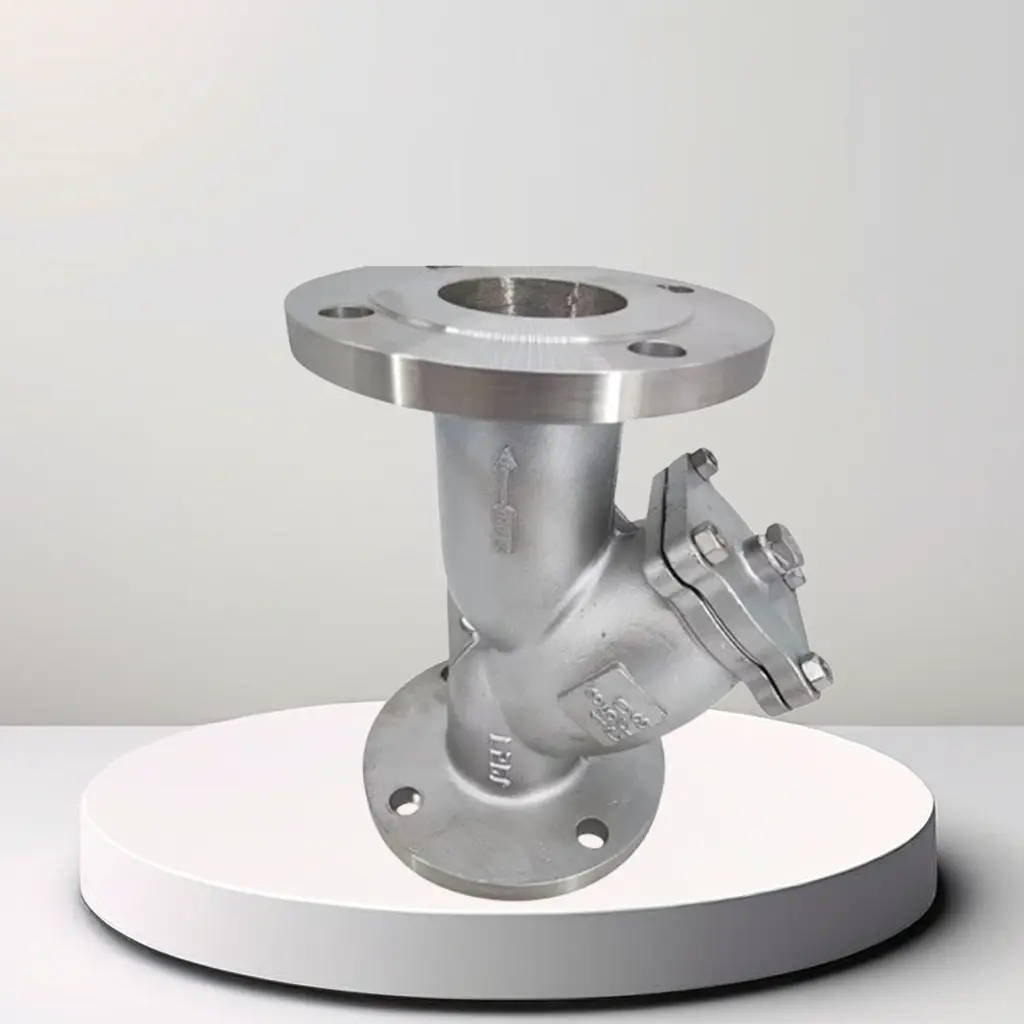

Product Description

A Brass Threaded Y-Type Strainer is a vital component used in fluid handling systems to filter out solid particles and debris from liquids. Here’s a detailed description covering its construction, operation, advantages, and applications:

Construction:

1. Material: Made from brass, which is known for its excellent corrosion resistance, durability, and suitability for a wide range of fluids including water, oil, and certain chemicals.

2. Y-Shaped Body: The strainer is shaped like the letter "Y", providing a larger filtration area compared to other strainer types. This design helps minimize pressure drop across the strainer and reduces the frequency of cleaning or maintenance.

3. Threaded Connections: Equipped with threaded ends (typically NPT or BSP), allowing for easy installation and removal from pipelines or equipment. Threaded connections provide a secure and leak-free seal.

4. Straining Element: Inside the Y-shaped body, there is a removable straining element, usually a mesh screen or perforated metal sheet. This element captures solid particles and debris from the fluid stream while permitting the clean fluid to pass through.

Operation:

- Filtration Process: As fluid flows through the strainer, solid particles and debris larger than the mesh or perforations are trapped by the straining element.

- Maintenance: Periodically, the straining element can be removed, cleaned, and replaced, ensuring continuous efficient filtration without interruption to the fluid flow.

Advantages:

- Protection: Protects downstream equipment such as pumps, valves, meters, and heat exchangers from damage caused by solid particles and debris.

- Durability: Brass construction offers robustness and resistance to corrosion, ensuring a long service life even in demanding environments.

- Ease of Installation: Threaded connections allow for quick and straightforward installation or replacement in piping systems.

Applications:

- Water Systems: Used in residential, commercial, and industrial water supply systems to filter out sediment and particulates.

- Oil and Gas Industry: Deployed in pipelines and refineries to safeguard pumps, compressors, and instrumentation from contaminants.

- Chemical Processing: Essential for filtering chemicals and solvents in industrial processes to maintain product quality and equipment integrity.

- HVAC Systems: Employed in heating, ventilation, and air conditioning systems to protect components from debris and extend their operational life.

Maintenance:

- Regular Inspection: Periodic inspection of the strainer to monitor buildup and ensure proper filtration performance.

- Cleaning: The straining element should be cleaned or replaced as needed to maintain optimal flow rates and system efficiency.

In summary, a Brass Threaded Y-Type Strainer is a reliable and durable filtration solution for various industries, providing effective particle removal and safeguarding downstream equipment. Its robust construction, easy installation, and minimal maintenance requirements make it an essential component in fluid handling systems where cleanliness and reliability are crucial.