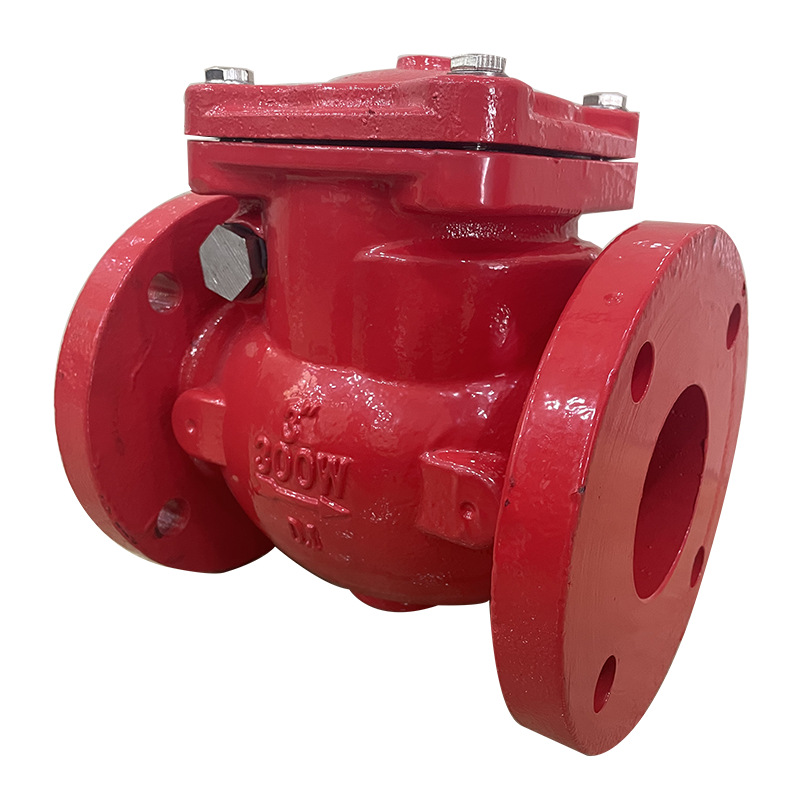

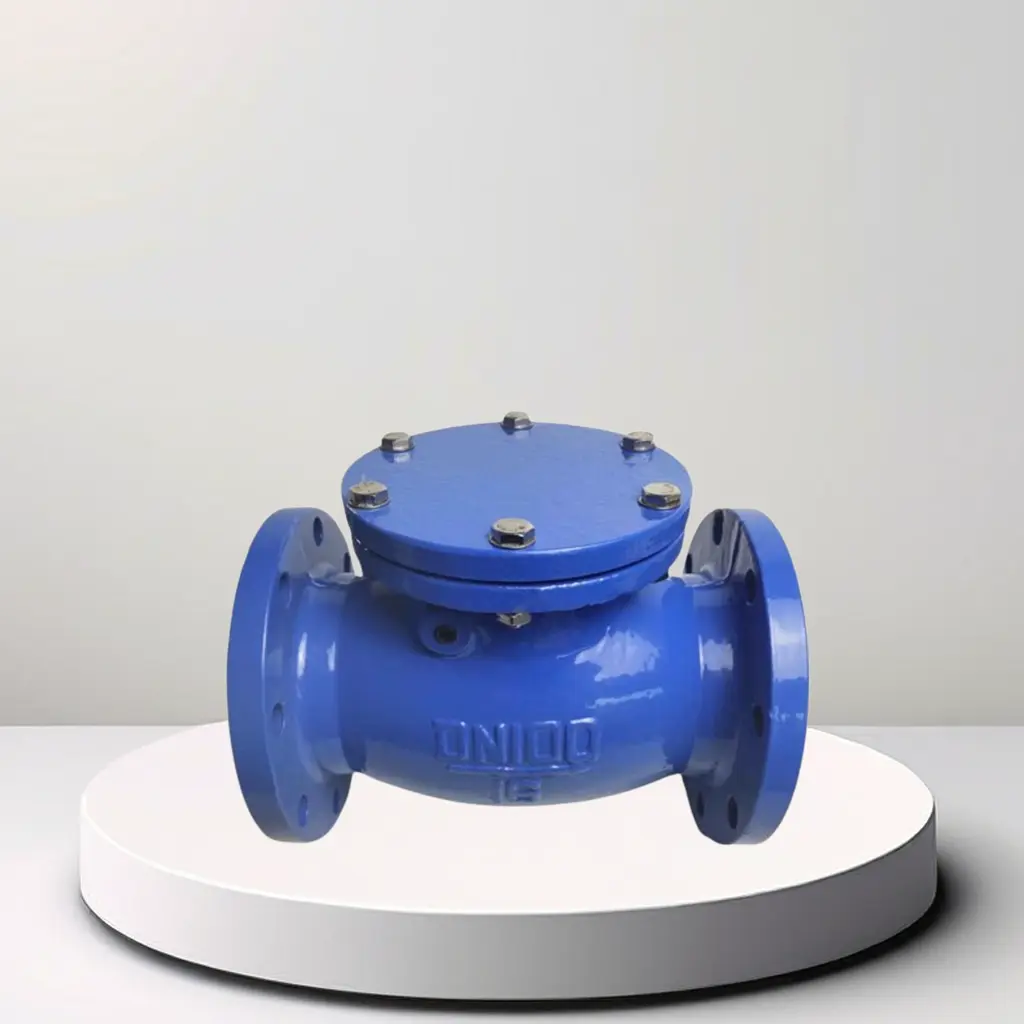

Product Description

A FM certified fire protection American standard swing check valve is a critical component in fire protection systems, designed to prevent the reverse flow of water or fire suppression agents. Here’s a detailed description of its features, construction, certification, and applications:

1. Construction and Materials:

- Body: Typically made of ductile iron (DI) or cast iron, providing strength and durability to withstand high-pressure environments.

- Seat and Disc: The valve contains a swing-type disc that opens with forward flow and closes tightly to prevent backflow. The disc and seat are often made of materials such as bronze or stainless steel to ensure longevity and resistance to corrosion.

- Connection Ends: It features American standard threaded or flanged ends for easy installation and compatibility with existing piping systems.

2. Design and Operation:

- Swing Check Mechanism: Operates on the principle of a swing check mechanism, where the disc swings freely on a hinge or pivot. This allows the disc to open fully with forward flow, facilitating unrestricted flow of water or fire suppression agents.

- Spring-loaded Option: Some models may include a spring-loaded mechanism to ensure positive closure of the disc, minimizing the risk of water hammer and enhancing reliability.

3. FM Certification:

- FM Approved: The valve is certified by FM Global (formerly Factory Mutual) after rigorous testing to ensure it meets their stringent standards for fire protection equipment.

- Compliance: Certification ensures that the valve complies with fire safety regulations and performance criteria, providing assurance of reliability and effectiveness in emergency situations.

4. Applications:

- Fire Protection Systems: Primarily used in fire sprinkler systems, standpipes, and other fire suppression installations to prevent the backflow of water or fire retardants.

- Building and Industrial Applications: Installed in commercial buildings, industrial facilities, and warehouses to safeguard against potential water contamination and system damage due to backflow.

5. Operation and Maintenance:

- Automatic Function: The swing check valve operates automatically based on flow direction, requiring no external power source for operation.

- Maintenance: Routine inspection is necessary to ensure the valve mechanism moves freely and the seating surfaces remain intact. Lubrication and replacement of seals may be required periodically to maintain optimal performance.

6. Installation and Compatibility:

- Threaded or Flanged Connections: Available with threaded connections (NPT) or flanged ends, allowing for easy integration into new or existing piping systems.

- Size Range: Available in a range of sizes to accommodate different flow rates and system requirements.

In summary, an FM certified fire protection American standard swing check valve is a crucial component in fire suppression systems, ensuring reliable operation and compliance with safety standards. Its robust construction, FM certification, and automatic operation make it indispensable for safeguarding buildings and industrial facilities against fire hazards by preventing backflow and maintaining system integrity during emergencies.