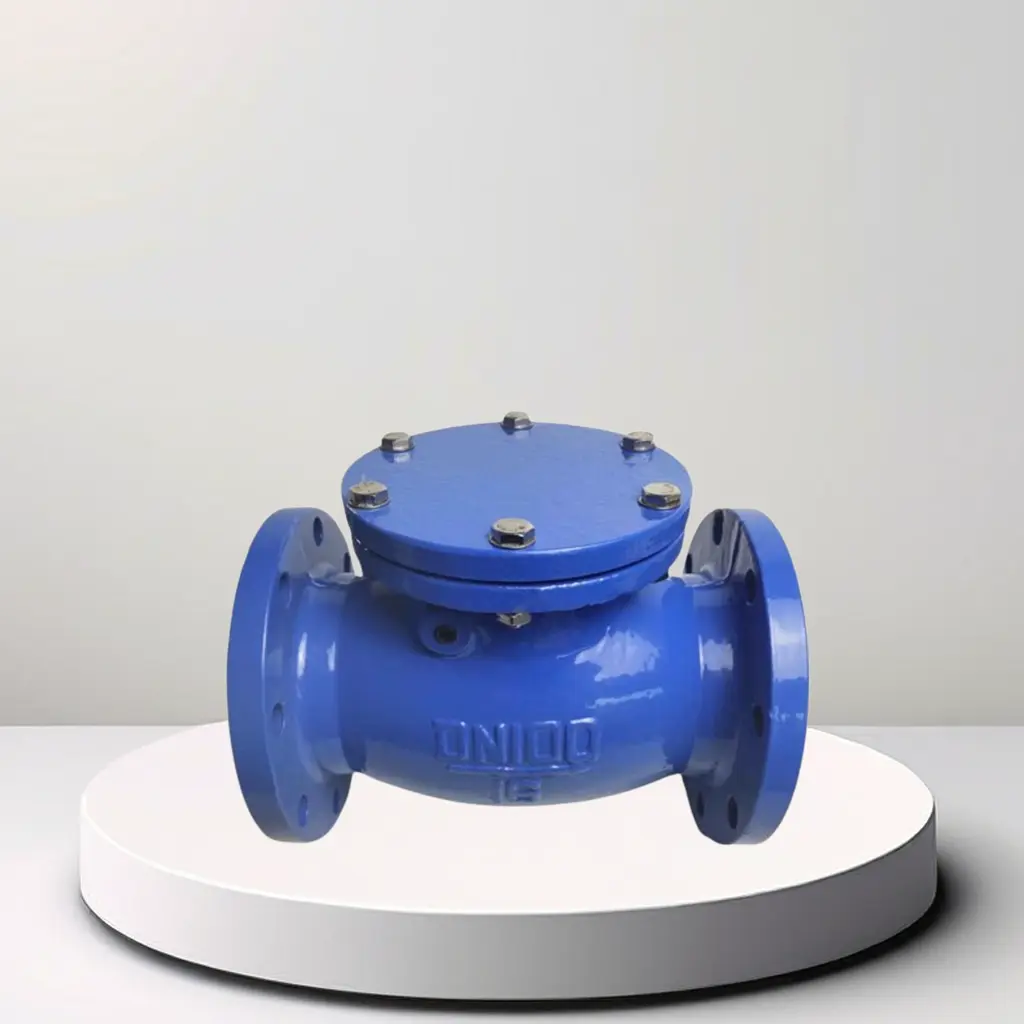

Product Description

A stainless steel 304/316 swing check valve is a crucial component used in pipelines to control the flow of fluids and prevent backflow. Here’s a comprehensive description of its features, construction, and applications:

1. Materials and Construction:

- Stainless Steel Grades: Available in either 304 or 316 stainless steel.

- Stainless Steel 304: Offers good corrosion resistance and is suitable for general-purpose applications where the fluid is not highly corrosive.

- Stainless Steel 316: Provides excellent corrosion resistance, especially in aggressive environments with chemicals, acids, or seawater.

- Valve Body: Typically constructed from stainless steel to withstand high pressures and temperatures.

- Swing Disc: The valve features a swing-type disc that opens automatically with forward flow of fluid and closes to prevent reverse flow. The disc is typically also made of stainless steel to ensure durability and corrosion resistance.

2. Design and Operation:

- Swing Check Mechanism: Operates on the principle of a swing check mechanism. When the fluid flows in the forward direction, the disc swings open to allow the fluid to pass through freely. When the flow stops or reverses, the disc swings back to its closed position under gravity and pressure to prevent backflow.

- Spring Option: Some models may include a spring-loaded mechanism to assist in closing the disc quickly and prevent water hammer effects.

- Sealing: The sealing surfaces of the valve (between the disc and seat) are designed to ensure tight shut-off and minimize leakage.

3. Applications:

- Industrial: Used in various industrial applications such as chemical processing plants, oil refineries, petrochemical plants, and power generation facilities where reliable flow control and prevention of backflow are critical.

- Water and Wastewater: Commonly employed in municipal water supply systems, wastewater treatment plants, and irrigation systems to maintain system integrity and prevent contamination.

- HVAC Systems: Utilized in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of chilled water, hot water, and refrigerants.

4. Installation and Maintenance:

- Connection Types: Available with threaded or flanged ends for easy installation into existing piping systems.

- Maintenance: Regular inspection and maintenance are recommended to ensure the valve operates smoothly and effectively. This includes checking the condition of the disc, seat, and seals, as well as lubricating moving parts if necessary.

5. Certifications and Standards:

- Some valves may comply with international standards such as ANSI (American National Standards Institute), ASTM (American Society for Testing and Materials), or API (American Petroleum Institute) standards for quality and performance assurance.

In summary, a stainless steel 304/316 swing check valve is designed for reliable flow control and prevention of backflow in various industrial and commercial applications. Its robust construction, corrosion resistance, and effective sealing mechanism make it an essential component in ensuring operational efficiency and system integrity.