Product Description

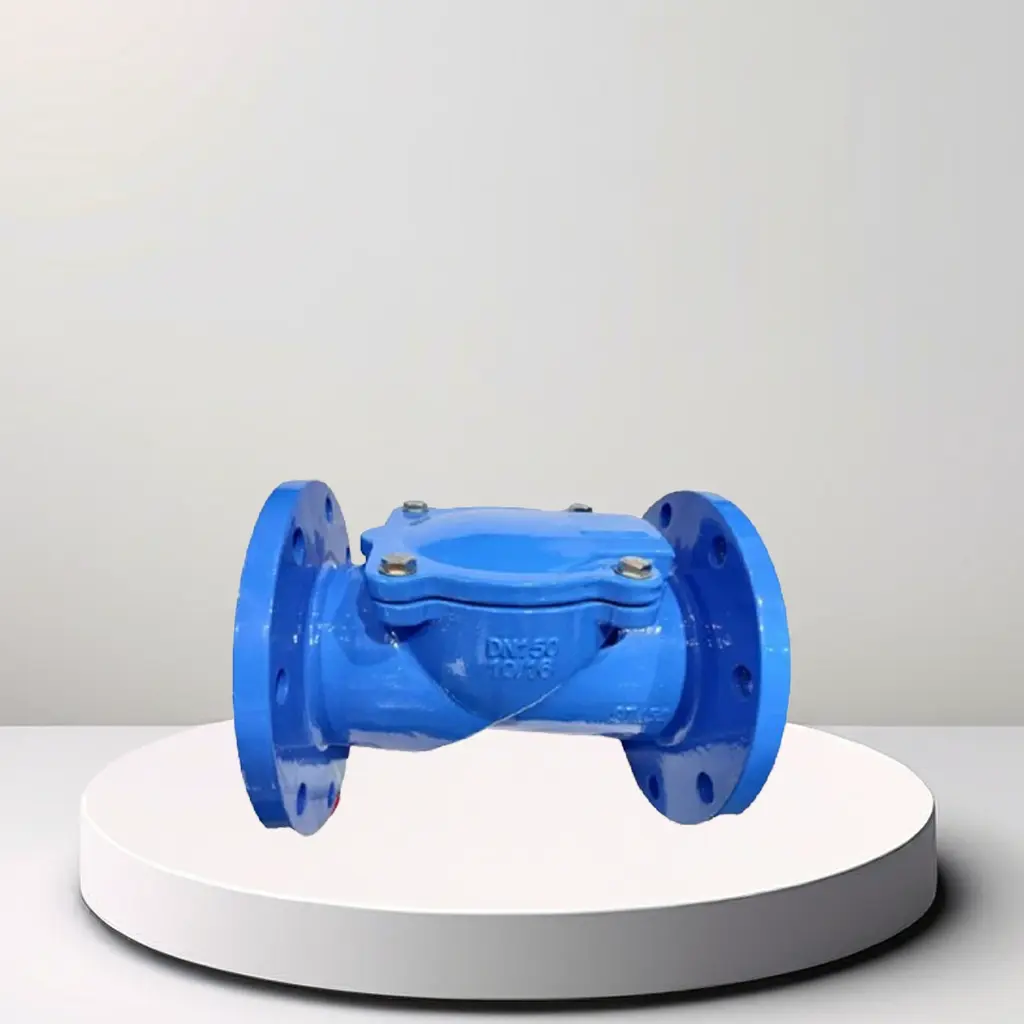

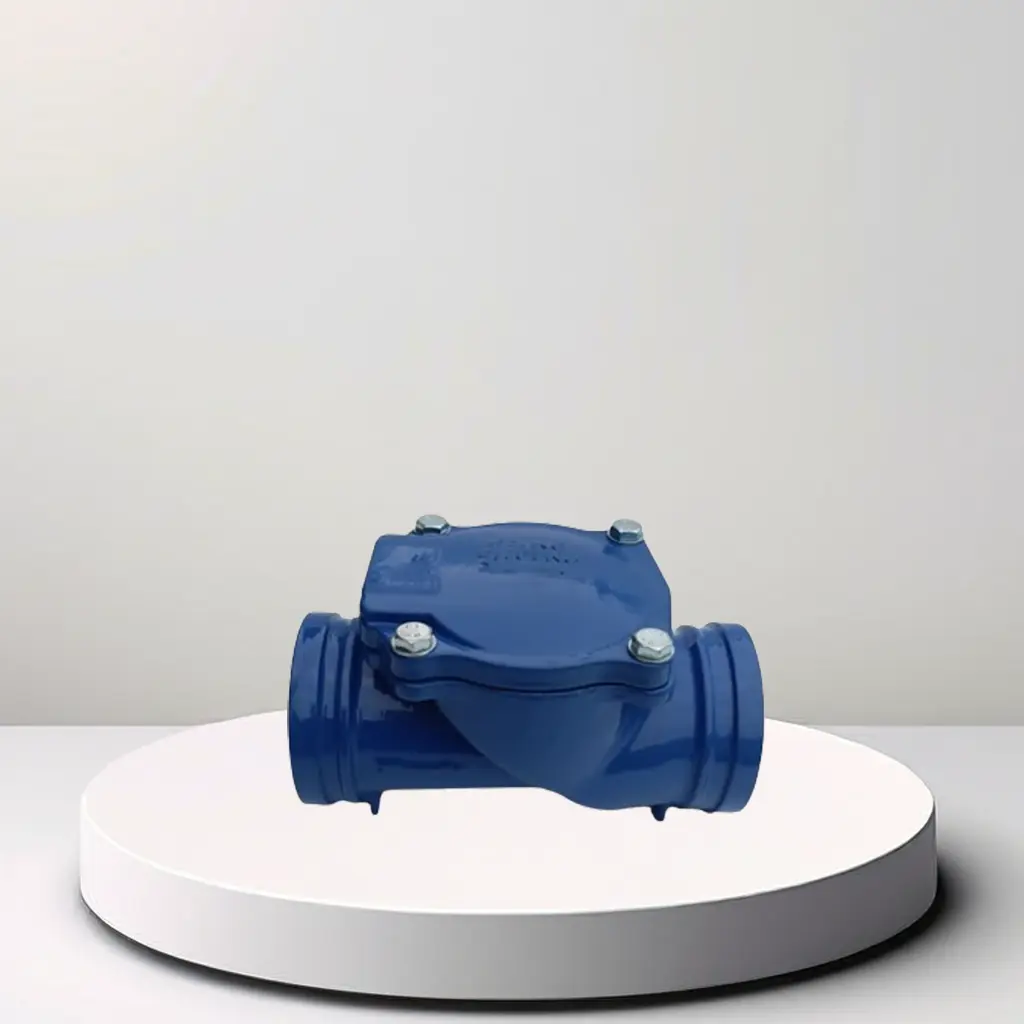

A rubber plate check valve, also referred to as a rubber flap check valve or rubber swing check valve, is a type of check valve designed to regulate the flow of fluids in pipelines. Here’s a detailed description of its construction, operation, applications, and benefits:

1. Construction:

- Rubber Flap or Plate: The key component of a rubber plate check valve is a flexible flap or plate made from rubber or elastomer materials. This flap is typically attached to a frame or body of the valve.

- Frame or Body: The valve body is often made of durable materials such as ductile iron, cast iron, or stainless steel, depending on the application requirements.

- Hinge Mechanism: The flap is hinged at one end within the valve body, allowing it to swing open when there is forward flow of fluid and close under its own weight or with minimal backpressure to prevent reverse flow.

2. Operation:

- One-Way Flow: The primary function of a rubber plate check valve is to allow fluid to flow in one direction while preventing flow in the opposite direction.

- Opening and Closing: When fluid flows in the correct direction, the flap or plate opens, allowing the fluid to pass through the valve unobstructed. When the flow stops or reverses, the flap or plate swings closed under gravity or minimal pressure, sealing the valve and preventing backflow.

- Sealing Mechanism: The sealing between the flap or plate and the valve seat ensures tight shut-off, minimizing leakage and maintaining system efficiency.

3. Applications:

- Wastewater Systems: Rubber plate check valves are commonly used in wastewater treatment plants and drainage systems to prevent backflow of sewage and wastewater.

- Stormwater Management: They are utilized in stormwater drainage systems to prevent flooding and ensure proper drainage.

- Industrial Processes: Found in various industrial applications where controlling fluid flow and preventing contamination or backflow are crucial, such as in chemical processing, mining, and pulp and paper industries.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems to regulate the flow of water, condensate, and other fluids.

4. Benefits:

- Cost-Effective: Rubber plate check valves are typically more economical compared to other types of check valves.

- Low Maintenance: They require minimal maintenance due to their simple design and fewer moving parts.

- Durability: The rubber flap or plate is resistant to corrosion and wear, providing long-term reliability.

- Efficient Flow Control: Ensures efficient fluid flow by preventing backflow and maintaining system integrity.

5. Installation and Considerations:

- Rubber plate check valves are available in various sizes and configurations to suit different pipe diameters and flow rates.

- Installation is straightforward, often involving flanged or threaded connections for easy integration into existing piping systems.

- Considerations include the compatibility of rubber materials with the type of fluid being transported and the operating conditions (temperature, pressure, chemical compatibility).

In summary, a rubber plate check valve is a versatile and cost-effective solution for controlling fluid flow in pipelines, ensuring reliable performance in diverse industrial, municipal, and commercial applications where preventing backflow is essential.