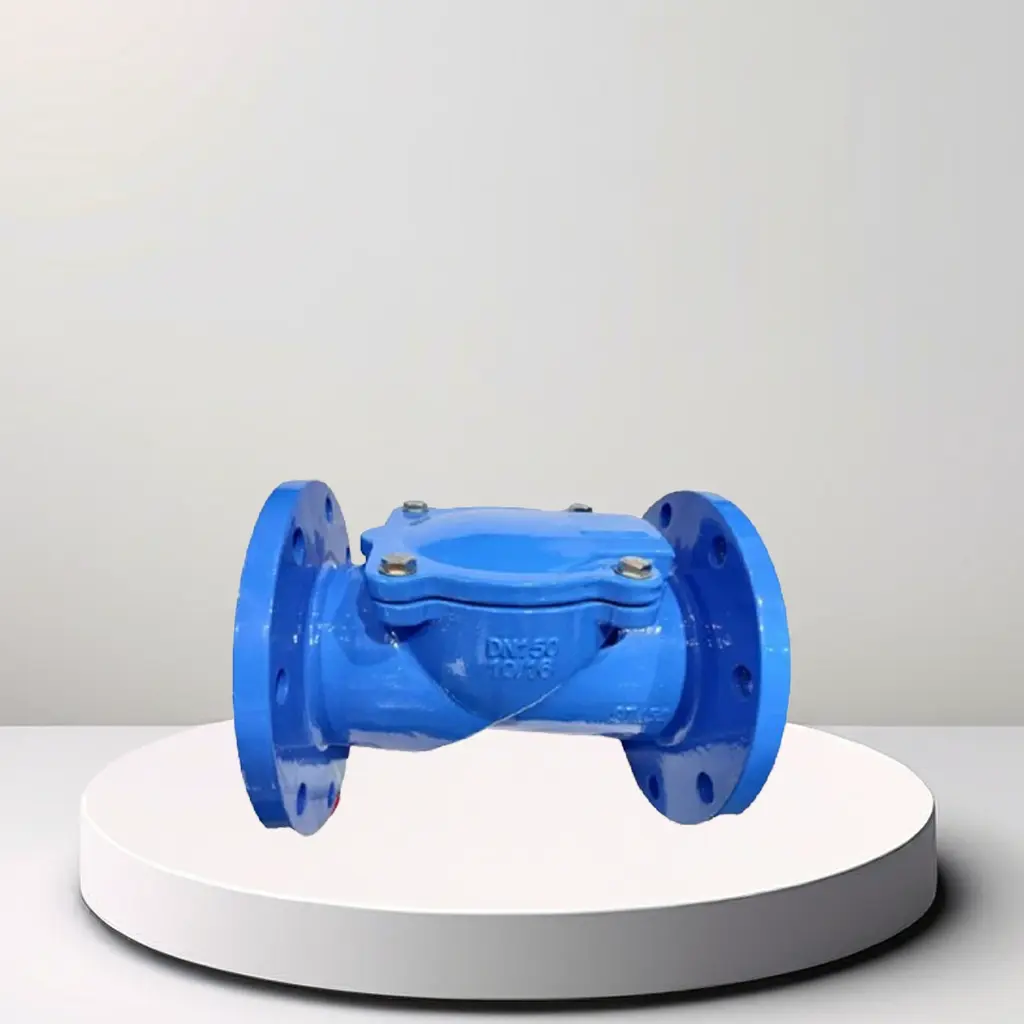

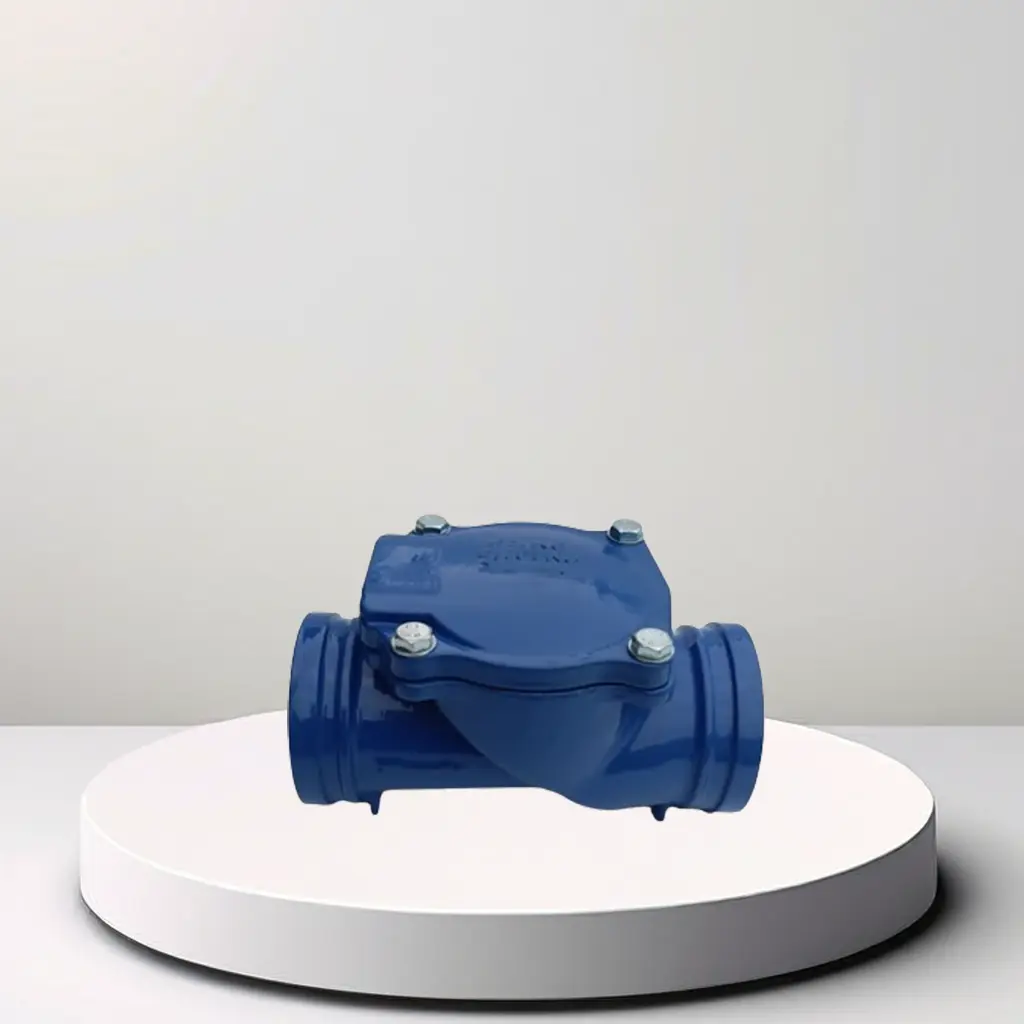

Product Description

A fire protection groove cast iron rubber plate check valve is a specific type of valve designed for use in fire protection systems to regulate the flow of water or fire-suppressing agents. Here’s a detailed description of its features, construction, and applications:

1. Construction and Materials:

- Body: The valve body is typically made of cast iron, known for its durability and strength. Cast iron is suitable for handling high-pressure applications common in fire protection systems.

- End Connections: It features grooved ends (often referred to as grooved fittings), which allow for quick and secure installation using mechanical couplings. This design facilitates easier and faster connection to fire sprinkler pipes or other firefighting equipment.

- Rubber Plate: The valve incorporates a flexible rubber plate or flap as the check mechanism. This rubber plate swings open to allow the flow of water or fire-suppressing agents during firefighting operations. It closes tightly under gravity or low backpressure to prevent reverse flow and maintain system integrity.

- Sealing: The sealing between the rubber plate and the valve seat ensures tight shut-off, minimizing leakage and ensuring efficient operation during emergencies.

2. Operation:

- One-Way Flow: The primary function of the rubber plate check valve is to allow fluid flow in one direction (forward flow) and prevent flow in the opposite direction (backflow).

- Emergency Response: During a fire event, the valve opens automatically to allow pressurized water or firefighting agents to flow from the supply lines into the firefighting system, such as sprinkler heads or standpipes.

- Reliability: The robust construction and simple design of the valve ensure reliable performance in critical situations, helping to control and suppress fires effectively.

3. Applications:

- Fire Protection Systems: Installed in fire sprinkler systems, fire hydrants, and fire suppression systems in buildings, industrial facilities, warehouses, and public spaces.

- Building Safety: Ensures compliance with fire safety regulations and standards by maintaining the integrity of fire protection systems and preventing contamination or damage to firefighting equipment.

- Industrial Use: Used in industrial settings where fire hazards exist, such as manufacturing plants, chemical processing facilities, and power generation stations.

4. Advantages:

- Durability: Cast iron construction provides strength and resistance to mechanical stresses and environmental factors.

- Ease of Installation: Grooved ends allow for quick installation and reconfiguration without the need for welding, which reduces installation time and labor costs.

- Low Maintenance: Requires minimal maintenance due to the durable materials and simple check valve design.

- Effective Flow Control: Ensures efficient flow regulation and prevents potential water hammer effects during firefighting operations.

5. Certifications and Compliance:

- Valves may comply with relevant standards such as UL (Underwriters Laboratories) and FM (Factory Mutual) approvals, ensuring they meet stringent safety and performance criteria for fire protection equipment.

In summary, a fire protection groove cast iron rubber plate check valve is a critical component in fire protection systems, providing reliable flow control and preventing backflow to ensure effective firefighting capabilities in emergency situations. Its robust construction, ease of installation, and adherence to safety standards make it essential for safeguarding lives and property from fire hazards.