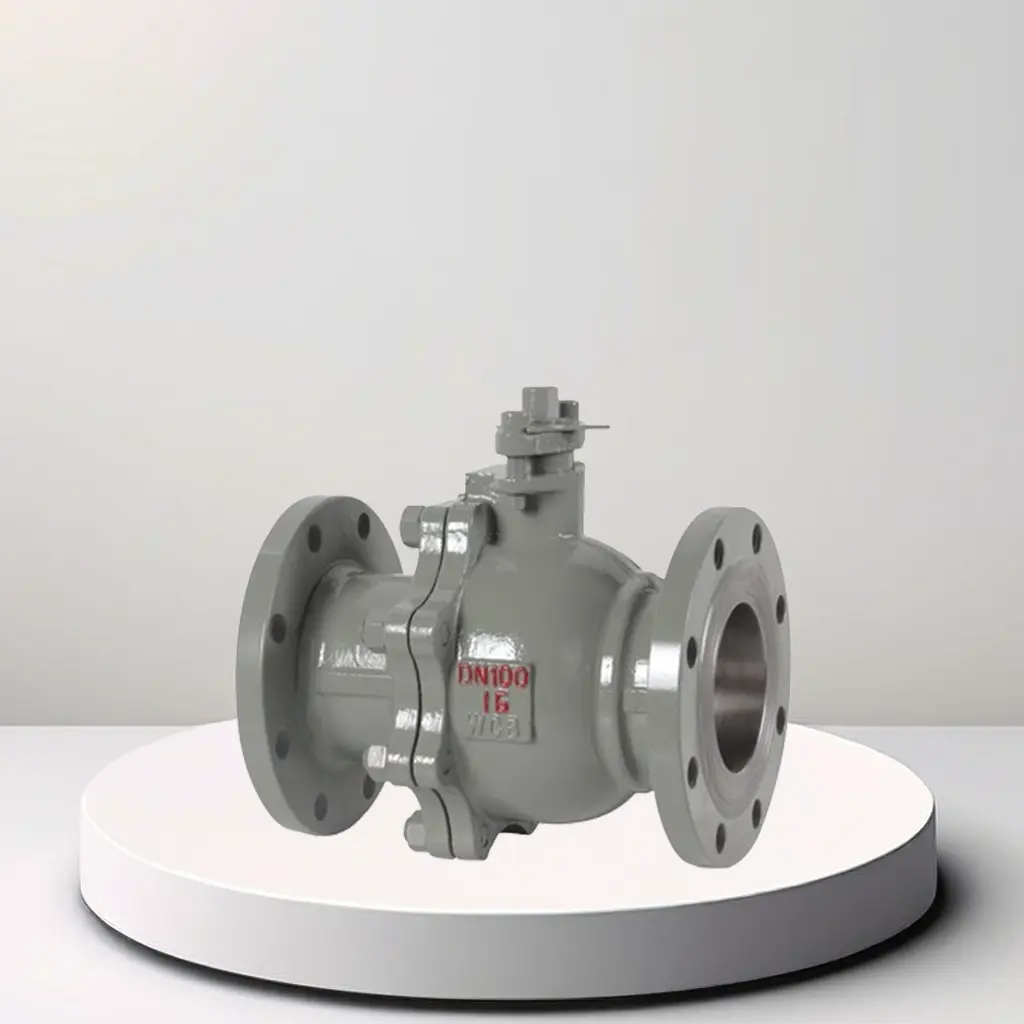

Product Description

A Stainless Steel Pneumatic Ball Valve is a high-performance valve designed for controlling the flow of fluids or gases in industrial applications. Here's a detailed description of its construction, operation, advantages, and applications:

Construction:

1. Valve Body: Made from stainless steel (typically grades such as 316 or 304), which provides excellent corrosion resistance, durability, and strength. Stainless steel is ideal for applications where exposure to corrosive environments is a concern.

2. Ball: The valve features a spherical ball with a hole (bore) through its center. The ball is typically made of stainless steel or another durable material, ensuring longevity and reliable performance.

3. Seats and Seals: The valve includes seats and seals made from materials such as PTFE (Polytetrafluoroethylene), which offer excellent chemical resistance and provide a tight seal to prevent leakage.

4. Actuator: Equipped with a pneumatic actuator, which operates using compressed air. This actuator is responsible for opening and closing the valve by rotating the ball within the valve body.

Operation:

- Pneumatic Actuation: Compressed air is supplied to the actuator, which moves a piston or diaphragm. This movement is transferred to the ball inside the valve, rotating it to either allow or block flow through the valve.

- Quick Response: Pneumatic ball valves offer rapid response times, making them suitable for applications requiring fast-acting flow control.

- Manual Override: Some pneumatic ball valves may include a manual override feature, allowing manual operation in case of power loss or during maintenance.

Advantages:

- Corrosion Resistance: Stainless steel construction ensures resistance to rust and corrosion, making the valve suitable for harsh environments and corrosive fluids.

- Durability: Stainless steel materials provide durability and longevity, reducing maintenance requirements and extending the valve's service life.

- Reliable Sealing: PTFE seats and seals ensure a tight shut-off, preventing leakage even under high-pressure conditions.

- Versatility: Suitable for a wide range of industries including chemical processing, oil and gas, water treatment, pharmaceuticals, and food processing.

Applications:

- Chemical Processing: Handles corrosive chemicals and fluids safely and reliably.

- Oil and Gas: Used in pipelines and refineries for flow control of oil and gas.

- Water Treatment: Controls water flow in treatment plants and distribution systems.

- Food and Beverage: Suitable for hygienic applications due to stainless steel construction.

- HVAC Systems: Controls air or water flow in heating, ventilation, and air conditioning systems.

Installation and Maintenance:

- Threaded or Flanged Ends: Available with threaded or flanged connections to suit different piping systems.

- Regular Inspection: Periodic inspection and maintenance ensure optimal performance and longevity.

In summary, a Stainless Steel Pneumatic Ball Valve combines the durability of stainless steel with the precision and reliability of pneumatic actuation, making it a versatile choice for demanding industrial applications requiring efficient flow control and resistance to harsh environments.