Product Description

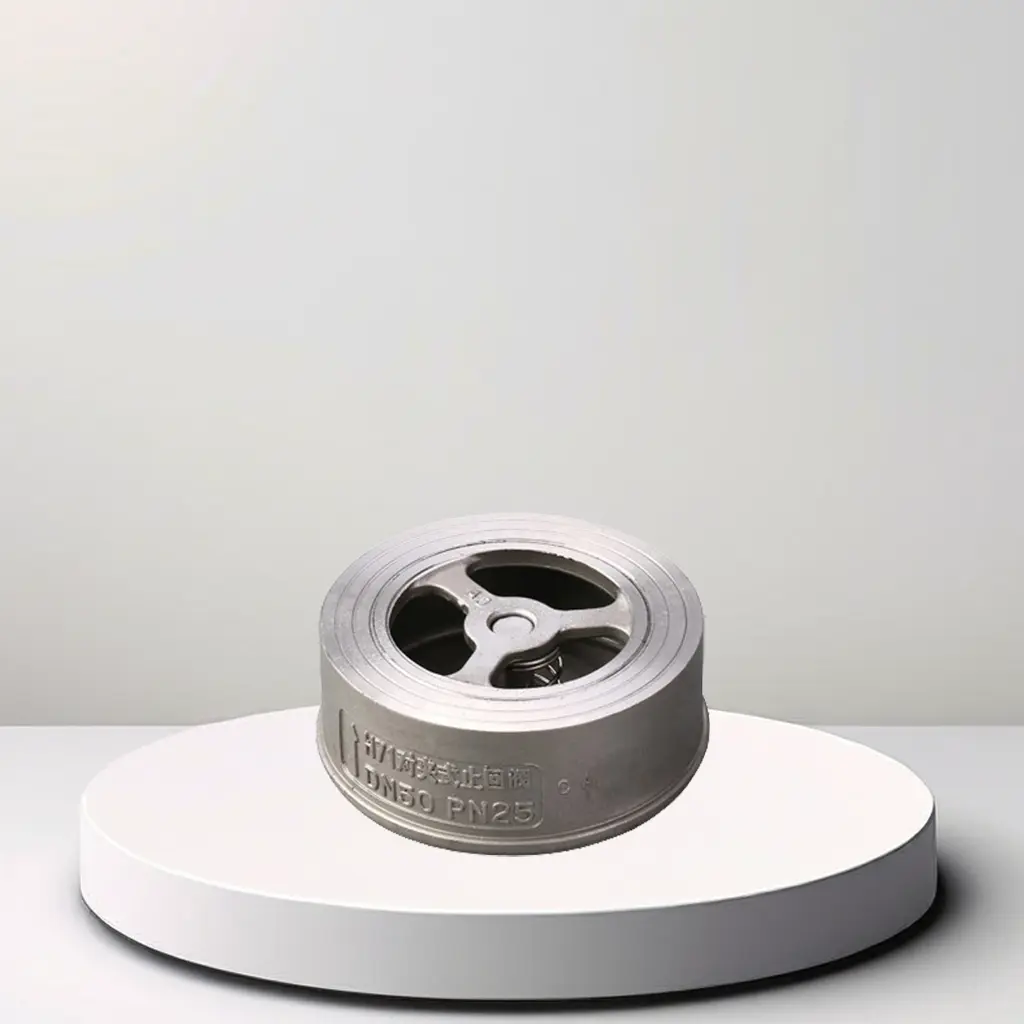

SS304/316 Wafer Check Valve

Introduction

The SS304/316 Wafer Check Valve is a high-quality valve designed to prevent backflow in pipelines. Made from stainless steel grades SS304 or SS316, this valve is ideal for various industrial, municipal, and commercial applications where durability, corrosion resistance, and reliable performance are essential.

Key Features

1. Stainless Steel Construction (SS304/316):

- Materials:

- SS304: Offers good corrosion resistance and is commonly used for general applications.

- SS316: Provides superior corrosion resistance, especially in chloride environments, making it ideal for more aggressive conditions.

- Durability: Both materials ensure high strength, resistance to wear, and a long service life.

2. Wafer Type Design:

- Structure: The wafer design is a thin, disc-like valve that fits between two flanges in a pipeline.

- Space Efficiency: Compact and lightweight, it requires less space compared to other valve types and is easy to install.

3. Check Valve Mechanism:

- Operation: Utilizes a disc or flap that opens to allow fluid flow in one direction and closes to prevent backflow.

- Self-Operated: Automatically manages flow direction without external control or power sources.

4. Corrosion Resistance:

- Coating: Typically features a polished or passivated finish to enhance resistance to oxidation and corrosion.

- Applications: Suitable for handling various fluids, including water, chemicals, and gases.

Technical Specifications

- Size Range: Typically available from 1 inch (25 mm) to 24 inches (600 mm), with custom sizes available for specific applications.

- Pressure Rating: Designed to handle pressures up to ANSI Class 150 or higher, depending on the application and valve specifications.

- Temperature Range: Operates effectively in temperatures from -20°C to 150°C (-4°F to 302°F), though higher temperatures can be accommodated with special materials or design modifications.

- End Connections: The wafer design fits between standard flanges, compatible with ANSI, DIN, and JIS standards for easy integration into existing pipelines.

Applications

- Water Supply Systems: Used in municipal and industrial water supply systems to prevent reverse flow and protect the integrity of the system.

- Wastewater Treatment: Applied in wastewater treatment facilities for controlling the direction of effluent flow.

- Chemical Processing: Suitable for handling various chemicals in industrial processes due to its corrosion-resistant materials.

- HVAC Systems: Integrated into heating, ventilation, and air conditioning systems to manage fluid flow and prevent backflow.

- Marine and Offshore Applications: SS316 variants are ideal for marine environments due to their excellent resistance to saltwater corrosion.

Advantages

1. Reliable Backflow Prevention: Ensures one-way flow of fluids to prevent contamination and system damage.

2. Durable and Corrosion-Resistant: SS304 and SS316 materials offer high strength and excellent resistance to corrosion and wear.

3. Compact and Space-Efficient: The wafer design requires minimal space and simplifies installation between flanges.

4. Low Maintenance: Self-operating mechanism requires minimal maintenance and offers long-term reliability.

5. Versatile Applications: Suitable for a wide range of applications, including water treatment, chemical processing, and HVAC systems.

Disadvantages

1. Pressure Drop: The disc mechanism may cause a small pressure drop across the valve.

2. Temperature Limitations: While generally versatile, extreme temperatures may require specific material considerations or design modifications.

3. Potential for Disc Wear: Over time, the disc or flap may wear out and require replacement, especially under high flow conditions.

Conclusion

The SS304/316 Wafer Check Valve is a versatile and durable solution for managing fluid flow in various systems. Its stainless steel construction provides excellent corrosion resistance, while the wafer design offers a compact and efficient installation option. With reliable backflow prevention and low maintenance requirements, this valve is an excellent choice for water supply, wastewater treatment, chemical processing, and HVAC applications.