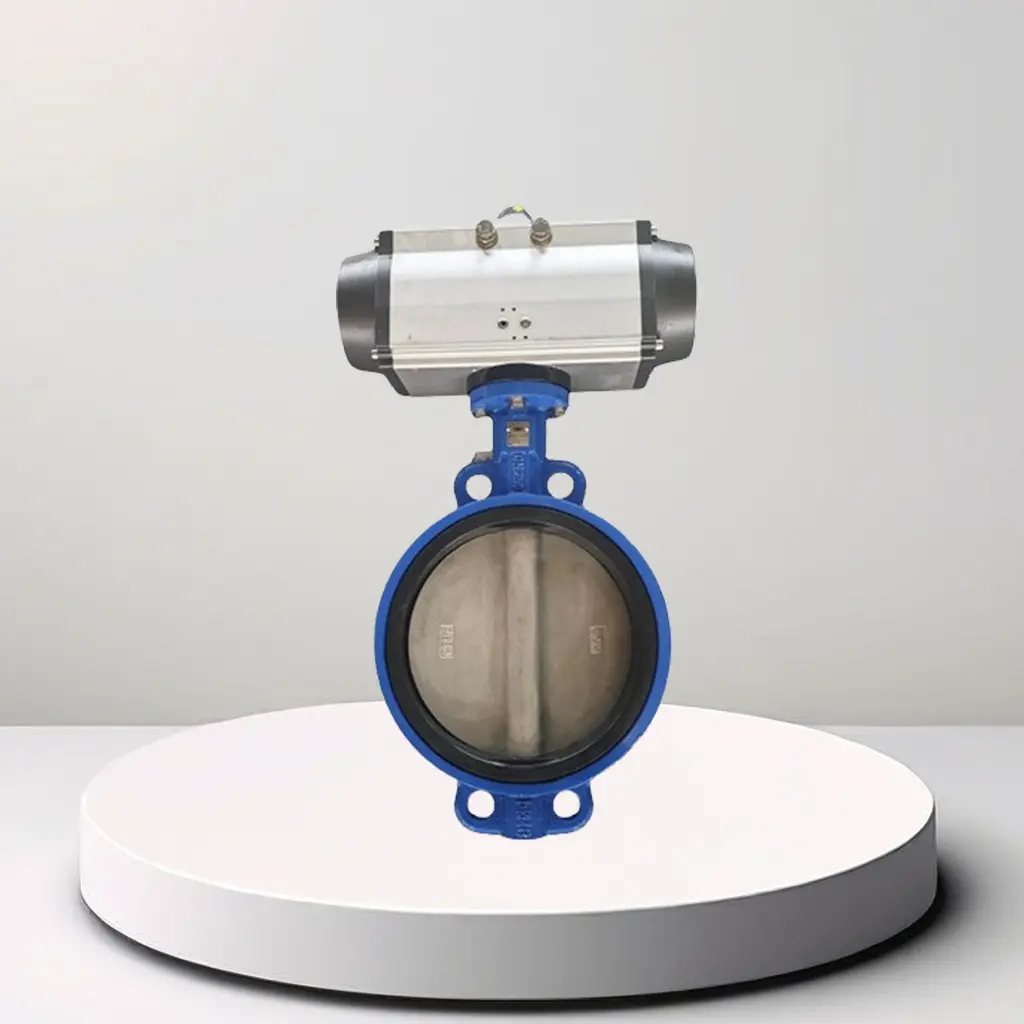

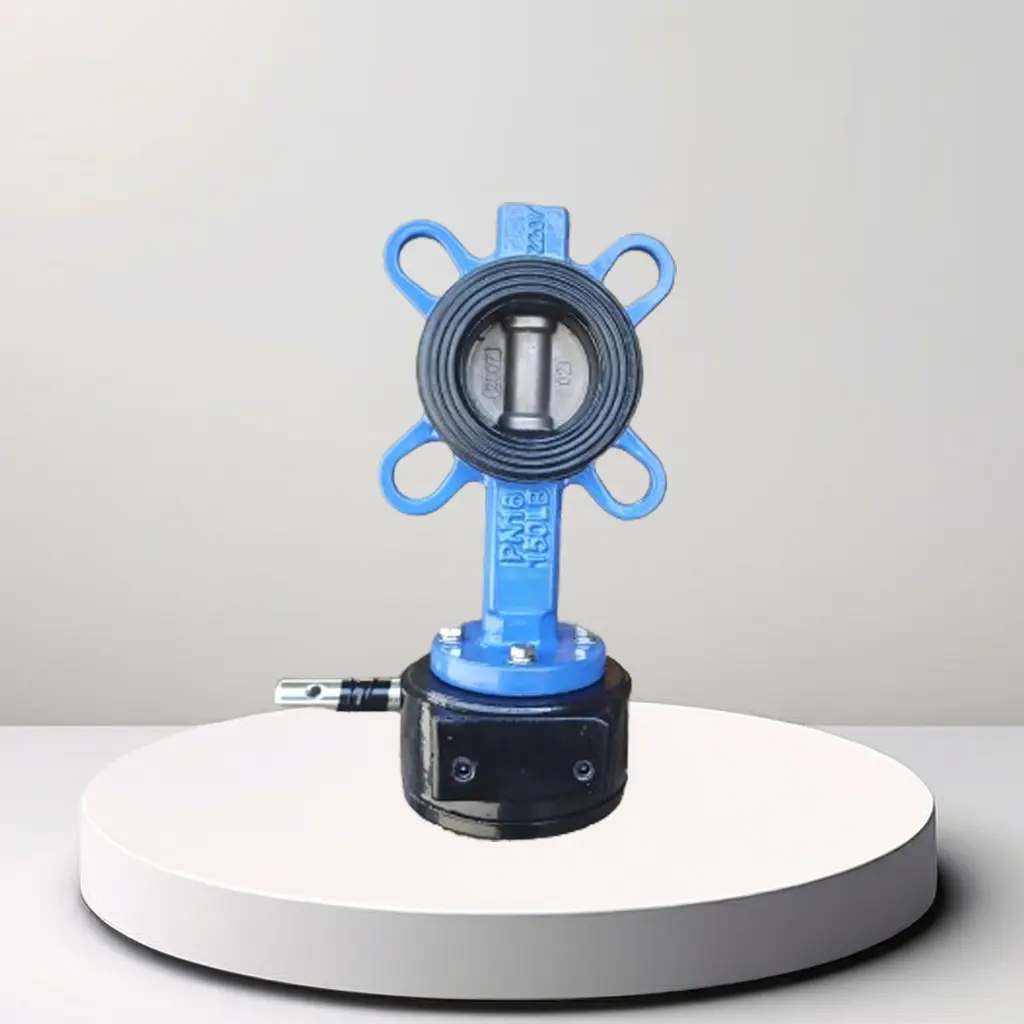

Product Description

A lever handle wafer butterfly valve is a type of quarter-turn valve that is used to control the flow of fluids (liquids, gases, or slurries) in a piping system. Here’s a detailed introduction:

Design and Structure

- Body: The valve has a wafer-style body, which means it is designed to fit between two flanges in the piping system. The wafer design is compact and allows the valve to be held in place by the tension of the flanges and bolts.

- Disc: The central component of the valve is the disc, which is mounted on a shaft. The disc is the part that rotates to open or close the valve.

- Seat: The seat provides a sealing surface for the disc. When the valve is closed, the disc presses against the seat to stop the flow of fluid.

- Shaft: The shaft connects the disc to the handle. It allows the disc to be rotated when the handle is turned.

- Handle: The lever handle is used to manually operate the valve. By rotating the handle 90 degrees, the disc can be moved from a fully open to a fully closed position, or vice versa.

Operation

- Opening: To open the valve, the lever handle is turned 90 degrees. This rotates the disc so that it is parallel to the flow of the fluid, allowing fluid to pass through the valve with minimal resistance.

- Closing: To close the valve, the handle is turned back 90 degrees. This rotates the disc so that it is perpendicular to the flow of the fluid, blocking the passage and stopping the flow.

Advantages

- Compact Design: The wafer design makes the valve compact and lightweight, which is ideal for applications where space is limited.

- Easy Operation: The lever handle allows for quick and easy operation, providing a simple way to control the flow of fluid.

- Cost-Effective: Compared to other types of valves, butterfly valves are generally more economical, both in terms of initial cost and maintenance.

Applications

Lever handle wafer butterfly valves are used in a wide range of applications, including:

- Water Treatment: Controlling the flow of water in treatment plants.

- HVAC Systems: Regulating air flow in heating, ventilation, and air conditioning systems.

- Chemical Processing: Handling various chemicals in industrial processes.

- Food and Beverage: Managing the flow of liquids in food and beverage production.

- Oil and Gas: Controlling the flow of petroleum products.

Materials

These valves can be made from a variety of materials depending on the application, including:

- Body: Typically made from cast iron, ductile iron, stainless steel, or PVC.

- Disc: Can be made from stainless steel, ductile iron, or other materials compatible with the fluid.

- Seat: Often made from elastomers such as EPDM, NBR, or PTFE for a good seal.

Maintenance

Lever handle wafer butterfly valves require minimal maintenance. Regular inspection and occasional lubrication of the handle and shaft may be necessary to ensure smooth operation. The seat and disc should also be checked periodically for wear and tear to maintain a proper seal.

In summary, a lever handle wafer butterfly valve is a versatile, cost-effective, and easy-to-operate valve used in various industries to control the flow of fluids. Its compact design, combined with its simple and quick operation, makes it a popular choice for many applications.