Product Description

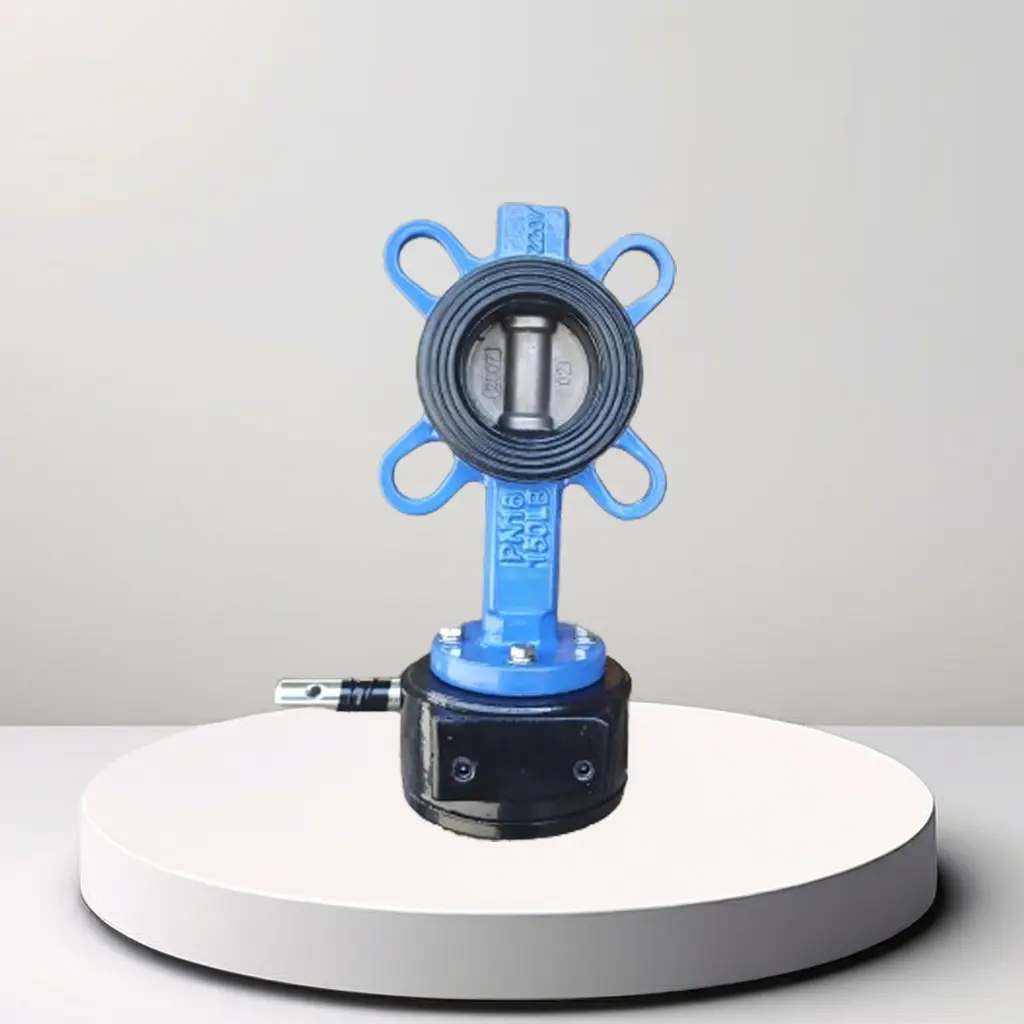

The Worm Gear Wafer Butterfly Valve is a widely used valve designed for efficient flow control in various industrial and commercial applications. Below is a detailed introduction:

1. Construction and Materials:

- Body Material: The valve body is typically made from durable materials such as cast iron, ductile iron, stainless steel, or carbon steel. The choice of material depends on the specific application and the nature of the fluid being controlled.

- Disc Material: The disc, which is the component that rotates to control fluid flow, is usually made from stainless steel, ductile iron, or other corrosion-resistant materials. The disc’s durability and resistance to wear are critical for the valve’s long-term performance.

- Seat Material: The seat, which ensures a tight seal when the valve is closed, is commonly made from elastomeric materials like EPDM, NBR, or PTFE. These materials are chosen for their chemical compatibility, temperature resistance, and sealing properties.

2. Design and Operation:

- Wafer Style: The valve has a wafer-style body, meaning it is designed to fit snugly between two flanges in a piping system without the need for additional support. This design is compact and lightweight, making it easy to install and ideal for applications where space is limited.

- Worm Gear Mechanism: The valve is operated using a worm gear mechanism, which consists of a worm (a gear in the form of a screw) that engages with a worm wheel attached to the valve’s stem. This mechanism allows for precise control of the valve’s position, enabling gradual and accurate opening or closing. The worm gear design also requires less force to operate the valve, making it easier to handle in various applications.

- Quarter-Turn Operation: The valve operates with a simple quarter-turn (90 degrees) of the disc to move from fully open to fully closed. This quick operation is efficient and suitable for applications requiring frequent adjustments.

3. Applications:

- Water Treatment: The Worm Gear Wafer Butterfly Valve is commonly used in water treatment plants for controlling the flow of water and other fluids. Its corrosion-resistant materials and precise control make it reliable in these environments.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, this valve regulates the flow of air, water, or steam. The wafer design is particularly useful in these systems where space and weight considerations are important.

- Industrial Processes: The valve is suitable for various industrial processes, including chemical processing, power generation, and manufacturing. Its robust construction allows it to handle different types of fluids, including corrosive and abrasive ones.

- Food and Beverage Industry: The valve’s hygienic design and the use of safe materials make it suitable for use in the food and beverage industry, where it controls the flow of liquids, including water, juices, and other consumable products.

4. Advantages:

- Compact and Lightweight: The wafer-style design makes the valve compact and lightweight, which is beneficial for installations where space is constrained and weight is a concern.

- Precise Control: The worm gear mechanism provides smooth and precise control over the valve’s position, allowing for accurate regulation of fluid flow.

- Easy Installation: The valve’s wafer design allows it to be installed between two flanges with minimal hardware, simplifying the installation process and reducing costs.

- Corrosion Resistance: The use of corrosion-resistant materials ensures that the valve can withstand exposure to various chemicals and fluids, extending its service life.

- Low Operating Torque: The worm gear design reduces the amount of force required to operate the valve, making it easier to open and close, even in large or high-pressure systems.

5. Installation and Maintenance:

- Installation: The valve is installed by positioning it between two flanges in a piping system. It is important to ensure that the valve is properly centered to prevent misalignment and leakage. The valve can be installed in both horizontal and vertical pipelines.

- Maintenance: Routine maintenance includes inspecting the worm gear mechanism, disc, and seat for signs of wear or damage. The valve’s simple design and durable materials mean that it requires minimal maintenance, reducing downtime and operational costs.

6. Limitations:

- Pressure and Temperature Limits: While the valve is suitable for many applications, it may not be ideal for extremely high-pressure or high-temperature environments. In such cases, alternative valve types or materials may be required.

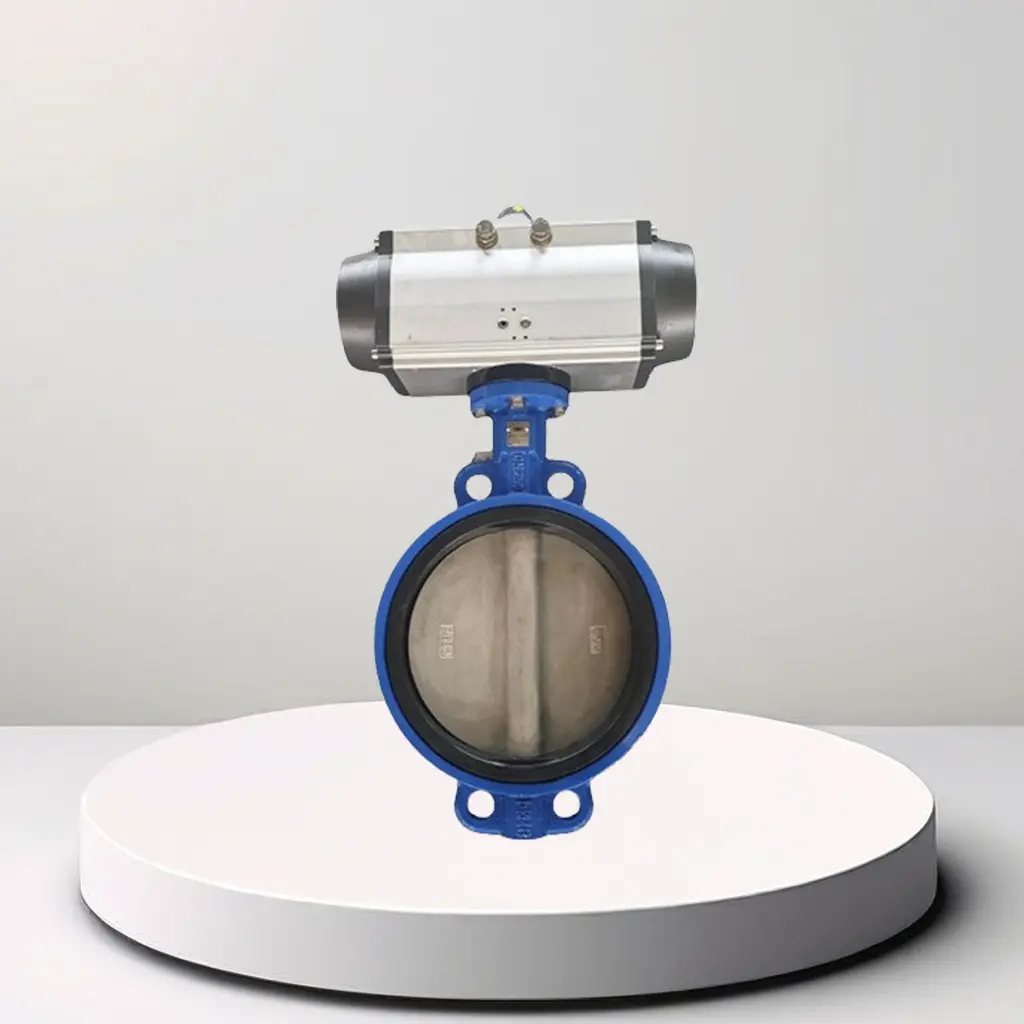

- Manual Operation: The worm gear operation is manual, which may not be ideal for automated systems. However, the valve can be fitted with electric or pneumatic actuators if automation is needed.

In summary, the Worm Gear Wafer Butterfly Valve is a versatile, compact, and reliable valve that offers precise control over fluid flow. Its worm gear mechanism, corrosion-resistant materials, and easy installation make it a popular choice in various industries, including water treatment, HVAC, and industrial processes.