Product Description

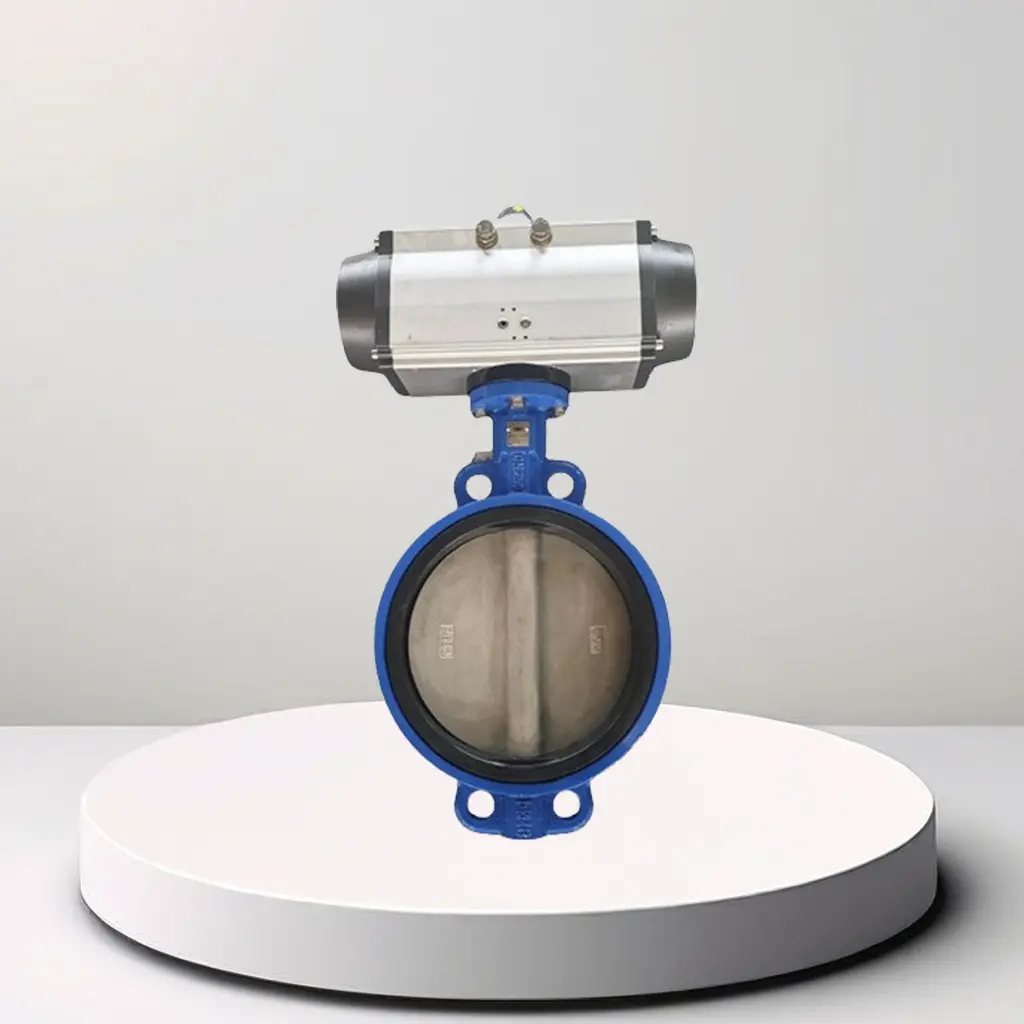

The Pneumatic Actuator Wafer Butterfly Valve is a type of industrial valve commonly used to regulate or isolate the flow of fluids, including gases, liquids, or slurries, within a pipeline. This specific valve design combines a butterfly valve with a pneumatic actuator, making it well-suited for automated or remote-controlled operations in various industrial applications.

Key Components and Structure:

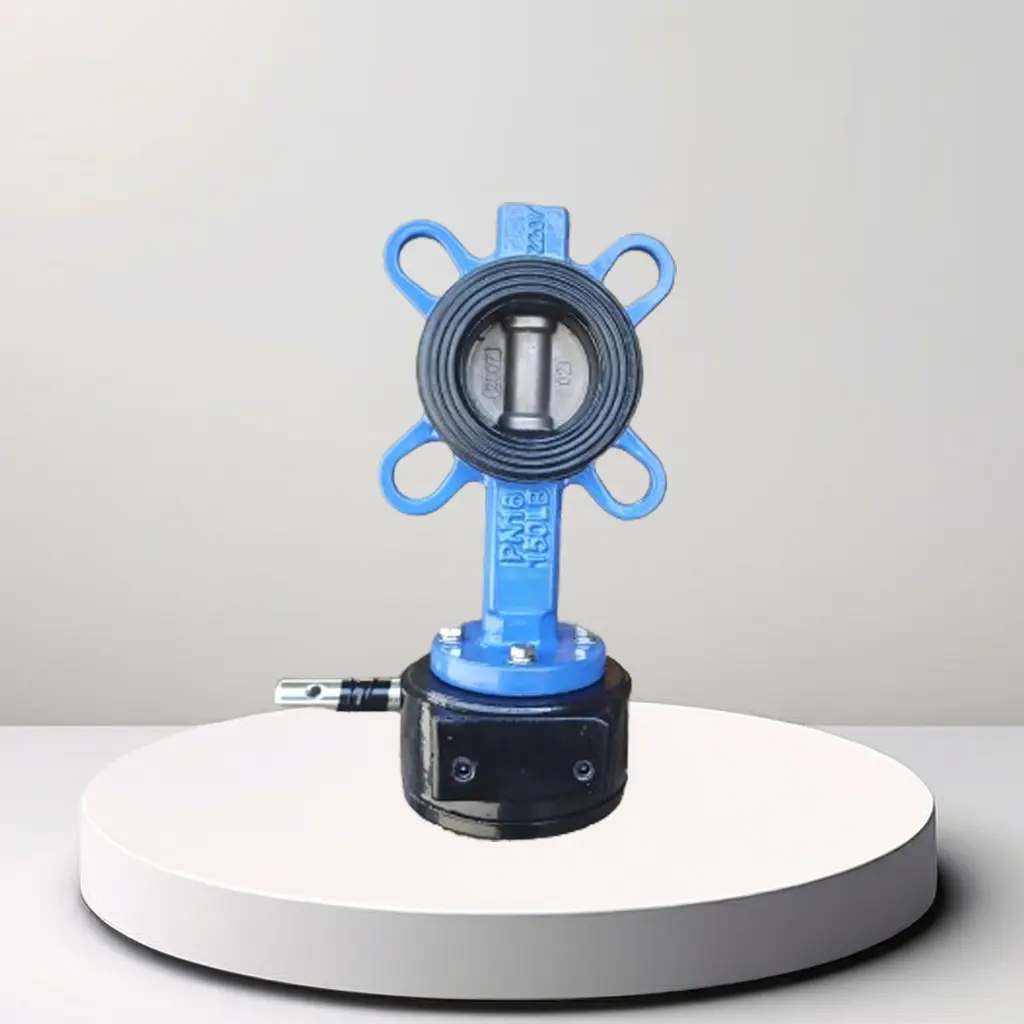

1. Butterfly Valve Body:

- Wafer Design: The wafer-style butterfly valve is designed to fit between two flanges in a piping system. It is held in place by bolts that pass through the flanges and around the valve body, without requiring additional gaskets. This design is compact and lightweight, making it ideal for applications where space is limited.

- Disc: The central component of the butterfly valve is the disc, which rotates to open or close the valve. When the disc is aligned with the flow, the valve is open; when it is perpendicular, the valve is closed. The disc can be made from various materials, such as ductile iron, stainless steel, or other alloys, depending on the application requirements.

- Seat: The seat is typically made from an elastomeric material and provides a seal between the disc and the valve body to prevent leakage when the valve is closed.

2. Pneumatic Actuator:

- Operating Mechanism: The pneumatic actuator operates using compressed air to generate mechanical motion. The actuator is connected to the valve stem, and when air pressure is applied, it rotates the valve disc to open or close the valve.

- Double-Acting vs. Spring-Return: There are two main types of pneumatic actuators used with wafer butterfly valves:

- Double-Acting Actuators: These require air pressure to both open and close the valve. They are more precise and offer better control but require a continuous air supply for both operations.

- Spring-Return Actuators: These use air pressure to move the valve in one direction (usually to open), and a spring mechanism returns the valve to its original position when the air pressure is released. This is useful for safety applications where the valve needs to automatically return to a fail-safe position in the event of a power loss.

3. Control and Automation:

- Positioners and Solenoid Valves: The pneumatic actuator can be equipped with positioners, which adjust the valve to a specific position based on control signals, and solenoid valves, which control the air supply to the actuator. These components allow for precise control and integration into automated systems, often used in process industries such as chemical, petrochemical, water treatment, and HVAC systems.

Advantages of Pneumatic Actuator Wafer Butterfly Valves:

- Fast and Reliable Operation: Pneumatic actuators provide quick response times and are highly reliable, making them suitable for applications requiring frequent valve operation.

- Compact and Lightweight: The wafer design minimizes the space required for installation, and the overall assembly is lighter compared to other types of valves with similar capabilities.

- Cost-Effective: These valves are generally more cost-effective compared to other automated valve types, especially when considering the installation and maintenance costs.

- Versatility: They can be used in a wide range of temperatures and pressures, depending on the materials used for the disc, seat, and body.

- Safety Features: Pneumatic actuators, especially those with spring-return mechanisms, can enhance safety by ensuring that the valve returns to a closed or open position in the event of a power or air supply failure.

Applications:

Pneumatic Actuator Wafer Butterfly Valves are widely used in industries such as:

- Water and Wastewater Treatment: For controlling the flow of water and treatment chemicals.

- HVAC Systems: To regulate airflow and water flow in heating and cooling systems.

- Chemical and Petrochemical: For managing the flow of various chemicals and gases in processing plants.

- Food and Beverage: Where sanitary valve designs are required for controlling the flow of ingredients and cleaning fluids.

- Pharmaceutical: In sterile environments where precise flow control and easy cleaning are essential.

In summary, the Pneumatic Actuator Wafer Butterfly Valve is a versatile, cost-effective, and efficient solution for fluid control in a wide range of industrial applications, providing reliable and automated operation with minimal maintenance requirements.